COMPANY PROFILE

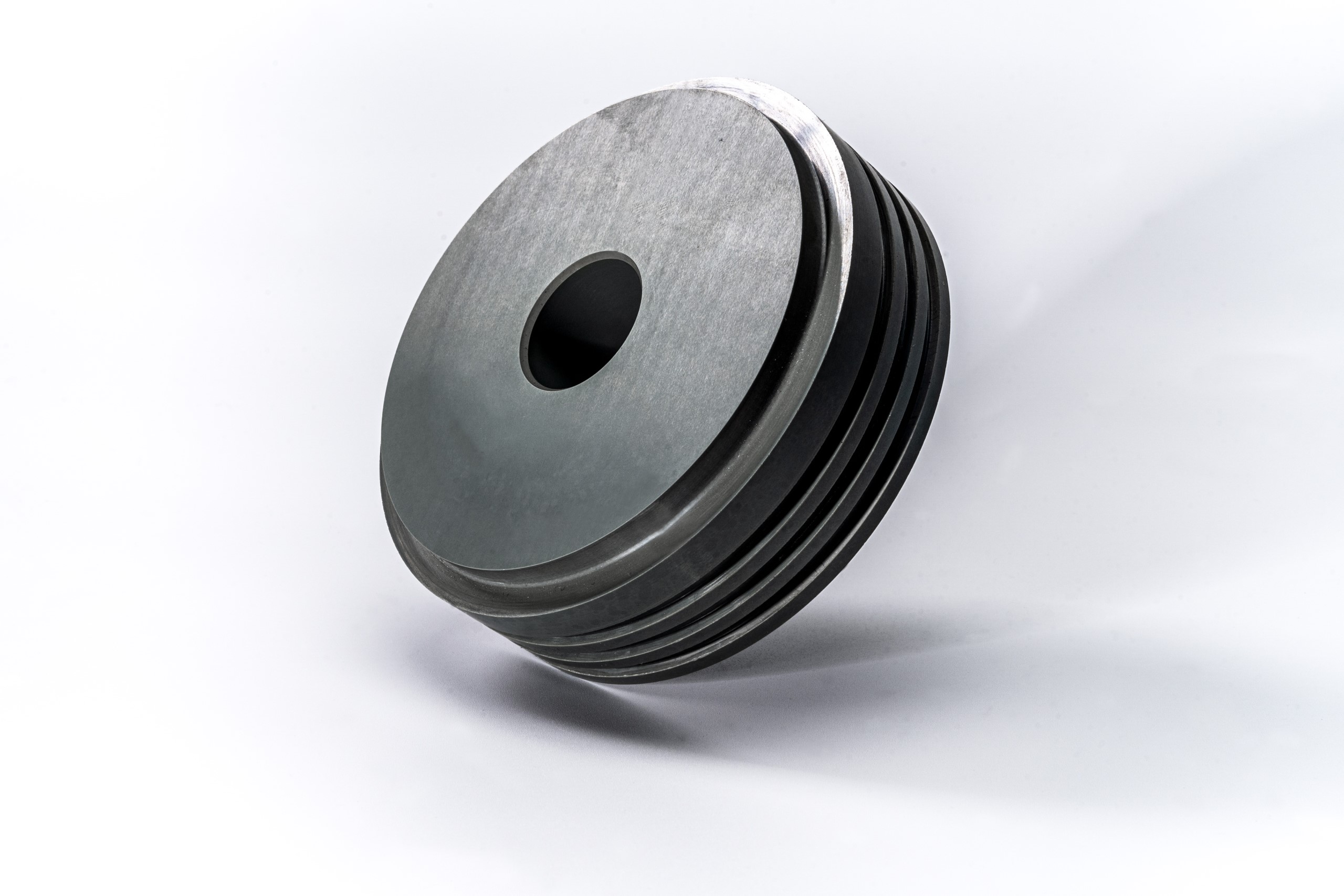

International Syalons (Newcastle) Limited is a leading manufacturer of advanced technical ceramics, primarily silicon nitride and sialon. These engineering ceramics enable us to solve wear, corrosion and thermal resistance problems in a wide range of industrial applications and markets, such as molten metal handling, oil and gas, chemical and process, automotive and aerospace.

Originally established in the late 1970s, the business of International Syalons is based in the North East of England and is the UK's leading producer of sialon and silicon nitride-based advanced ceramics. Our business was the first to patent and market sialon ceramics and has over 40 years experience in the development of advanced silicon nitride-based ceramics. We are leading experts in the field.

In 2018 International Syalons were acquired by CALSITHERM, who are best known for their 40 years of production of outstanding calcium silicate products, for a range of applications including; internal insulation, thermal insulation, non-ferrous metal casting, fire protection, domestic fireplaces, and plant construction. Having been a family run business since 1977, CALSITHERM are the only German producers of calcium silicate, with their headquarters located in Paderborn DE, the Group also has production and sales companies under the SILCA brand name in Mettmann DE, Amsterdam NL, Scorze IT, Dowerglen ZA, Querétaro MX, and Kuala Lumpur MY, as well as strategic partners in Brazil, Denmark and USA.

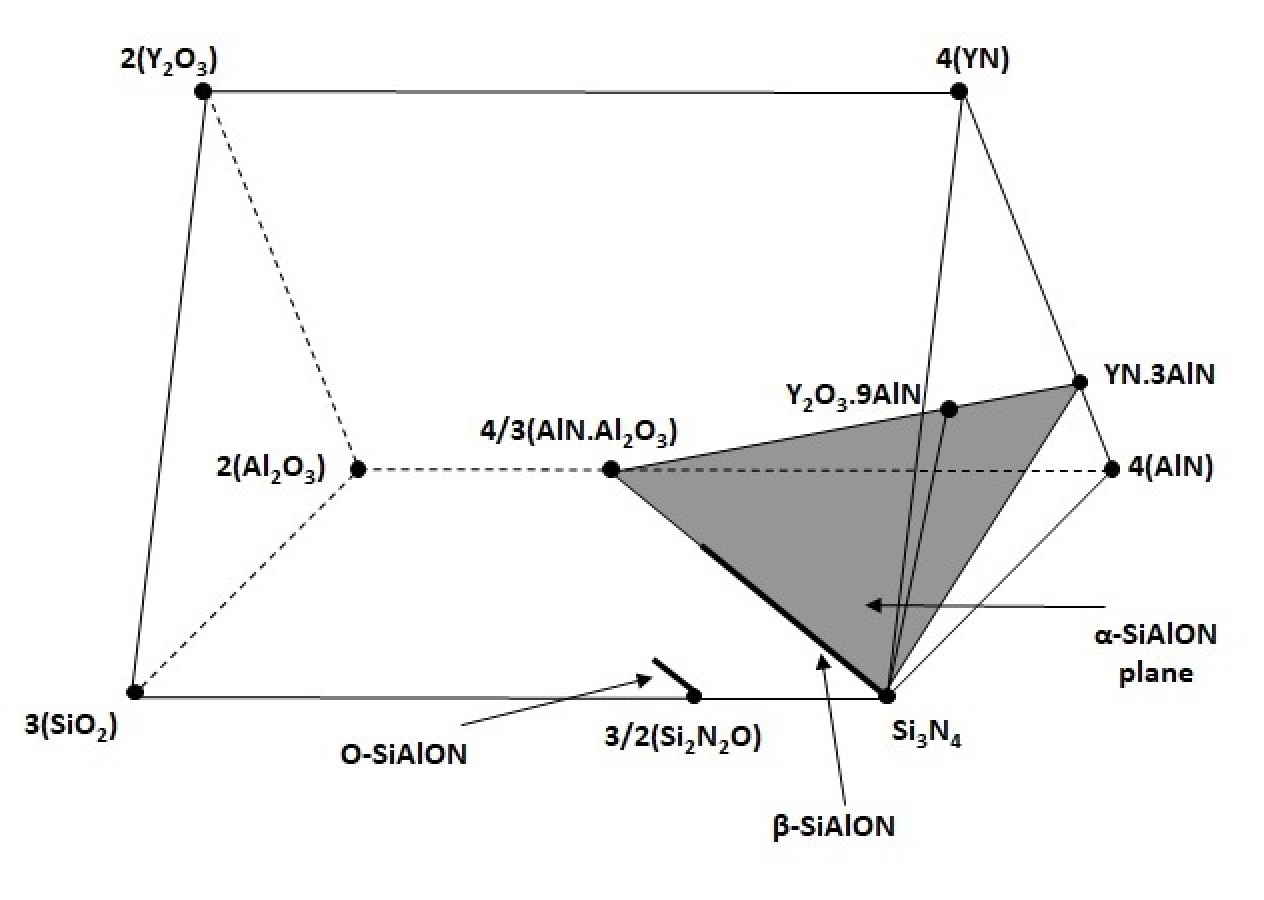

Sialons are silicon nitride based-technical ceramics which are characterised particularly by outstanding wear and corrosion resistance. We manufacture five grades of sialon and silicon nitride ceramic and composites each with a unique set of properties. In addition, International Syalons also offer a range of advanced alumina, zirconia and silicon carbide ceramics which complement our sialons in many industrial wear applications.

International Syalons are committed to providing world-class fine ceramic solutions to your industrial materials requirements. Our silicon nitride and sialon ceramics offer wear, corrosion and thermal resistance and are available for example as ceramic tubes, tiles, wear liners, foundry products and many more. In addition, our research and development department, in collaboration with world-renowned Institutes and Universities, are continuing to develop new materials, composites and cutting-edge fabrication processes to ensure our customers are getting the best advanced silicon nitride ceramics available.

For more information please call +44(0)191 2951010 or email for an initial consultation with our technical sales team or send us a Request for Quote.

Explore the discovery of sialon ceramics

What are sialon ceramics?

Syalon 101 is a grade of sialon which offers the best general combination of properties. These include high strength, hardness and toughness as well as excellent corrosion resistance.

Syalon 050 is suited to wear and high temperature applications. It has extreme hardness combined with high strength and can be used in applications up to 1400°C in air.

Zircalon 30 is a co-stabilised zirconia-based ceramic with an alumina matrix, which is reinforced by self-grown alumina-based platelets and offers outstanding fracture toughness.