SYALON 050

Syalon 050 is an advanced silicon nitride (Si₃N₄) ceramic offering outstanding wear, corrosion, oxidation and high temperature creep resistant properties.

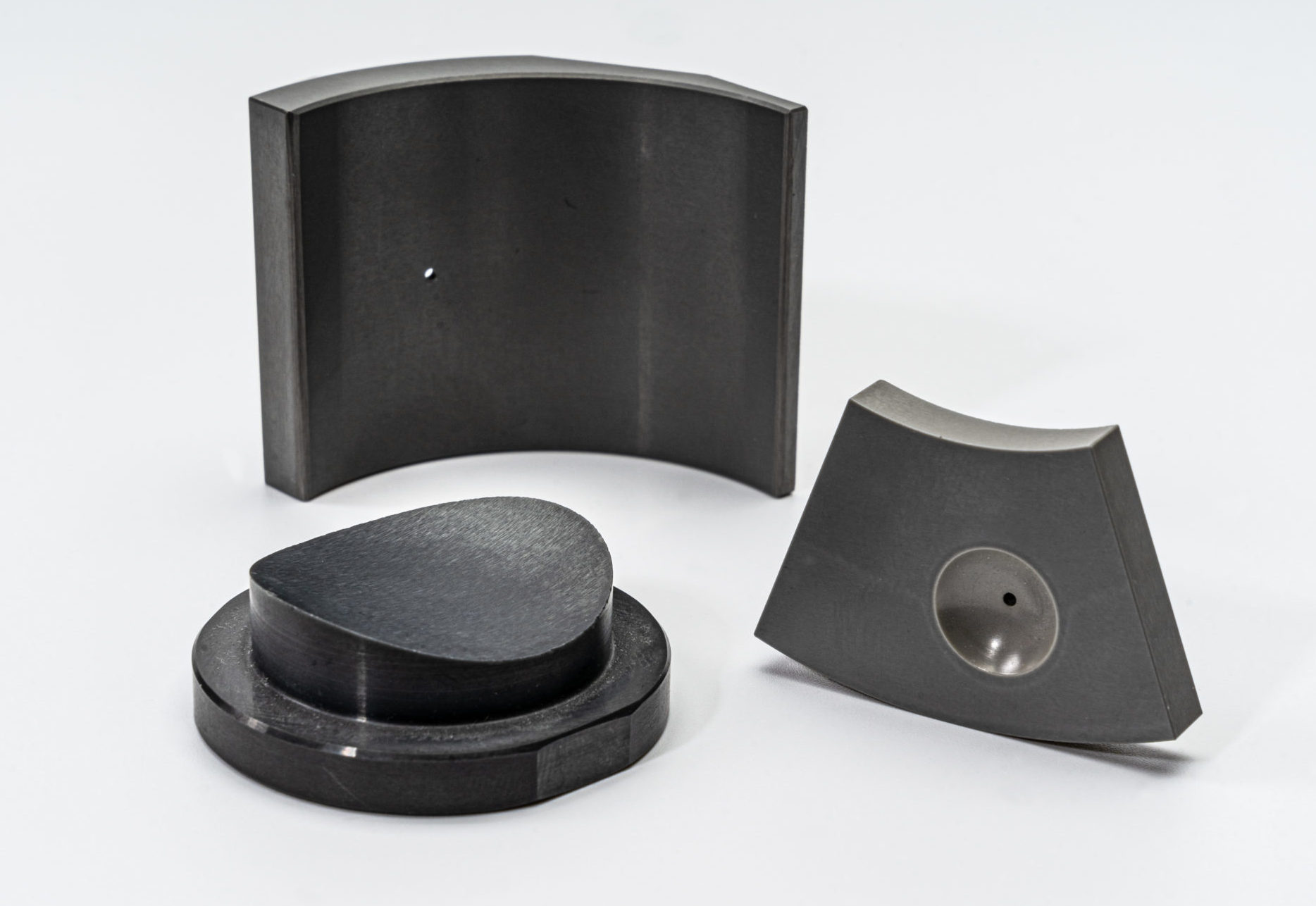

Syalon 050 is a member of the Si–Al–O–N family, the first group of man-made ceramic alloys, and has been specifically designed for high performance under arduous wear conditions. Based on silicon nitride, Syalon 050 is a mixed α/β-sialon advanced ceramic and has been designed to have extreme hardness and chemical and thermal stability.

Syalon 050 is a speciality material which is intended for industrial wear applications in which excellent wear, corrosion and thermal resistance are required. It also has excellent high temperature properties, maintaining good mechanical strength up to 1400°C as well as chemical stability to many molten metals and acids and alkalis.

The tables below list typical thermomechanical and electrical property, and corrosion resistance data for Syalon 050.

Syalon 050 - Physical Property Data

Syalon 050 - Corrosion Behaviour in Acids and Alkalis

Syalon 050 - Corrosion Behaviour in Molten Metals

The successful integration of advanced technical ceramics into engineering systems requires close collaboration between you, the end-user, and ourselves, the material manufacturer. Please call +44(0)191 2951010 or email for an initial consultation with our technical sales team, or send us a Request for Quote.

In addition, see our resources section for guides on designing with ceramics and more property data comparing Syalon 050 with other engineering ceramics.

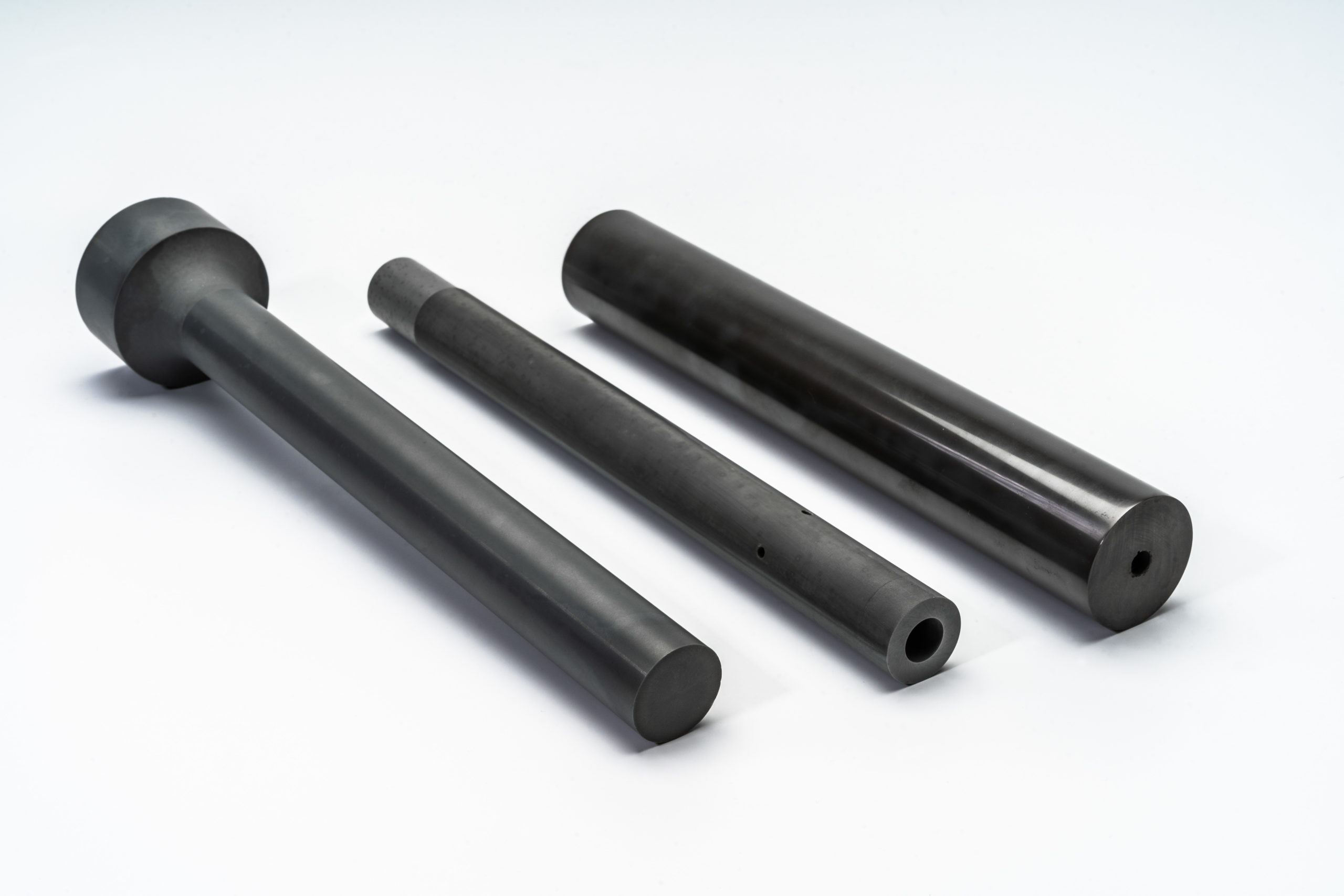

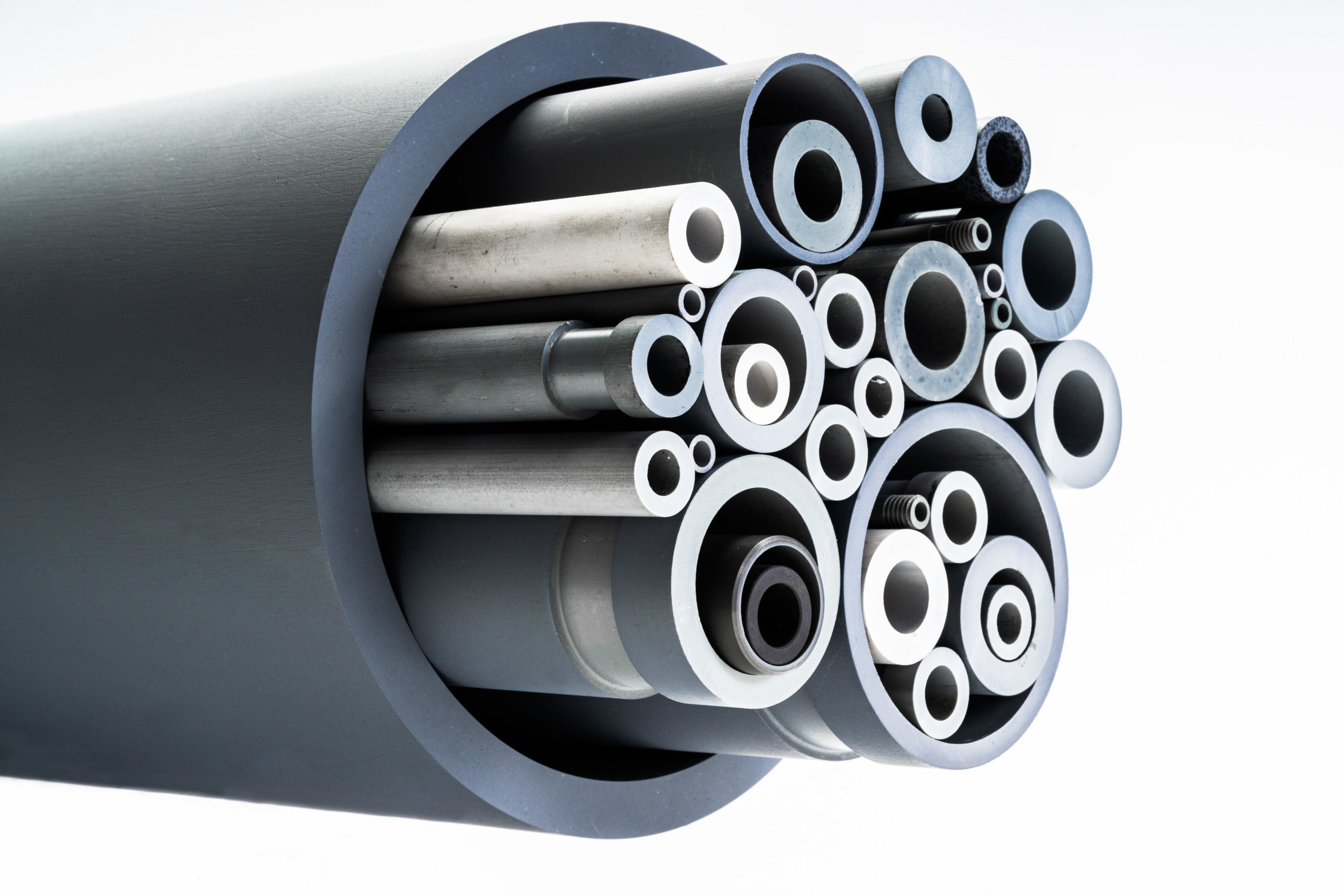

International Syalons manufacture a range of silicon nitride and sialon advanced ceramic thermocouple protection sheaths for use in the aluminium and molten metal handling industries.

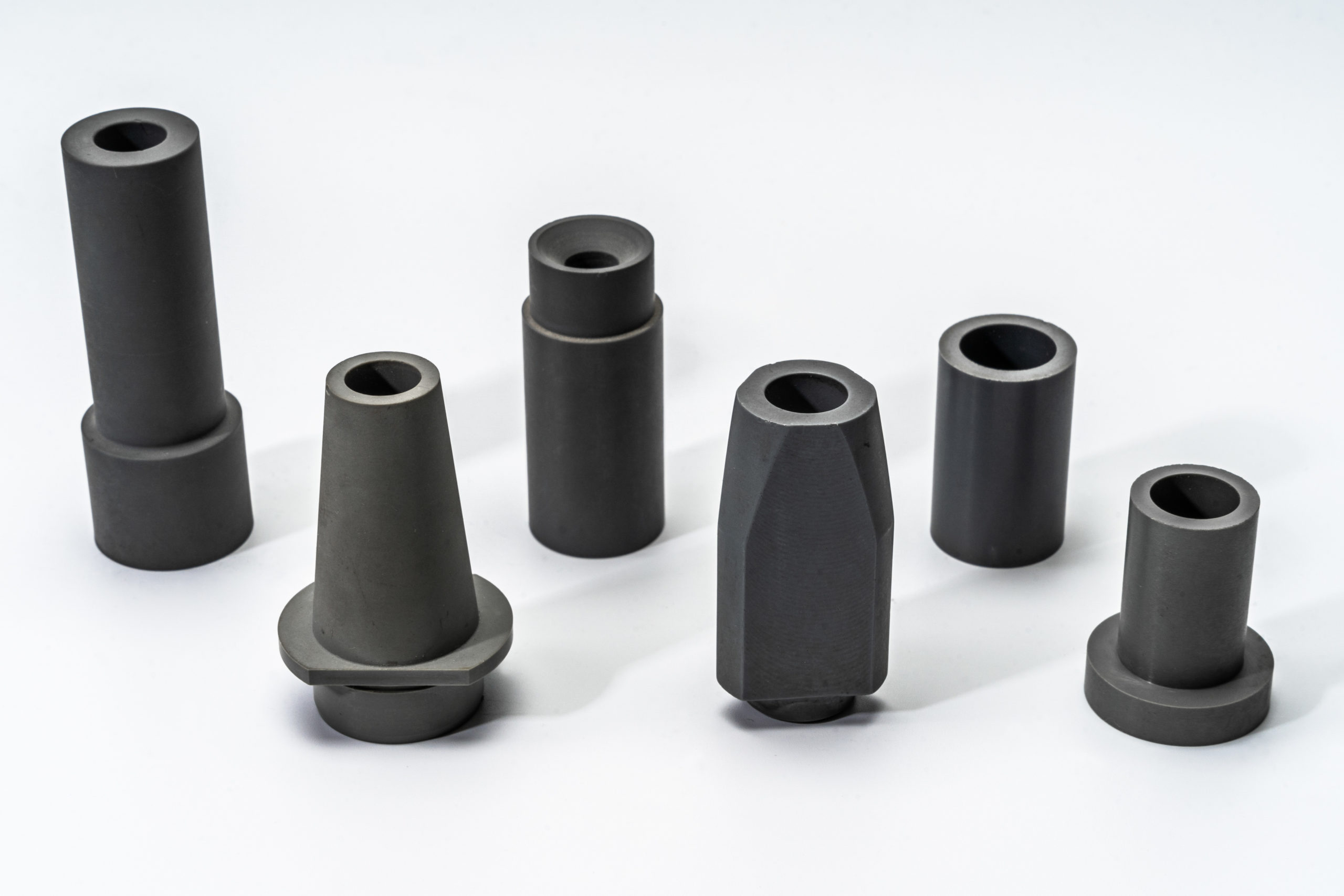

Syalon is the preferred choice when looking to improve nozzle wear resistance, outperforming many competitive materials such as alumina and tungsten carbide.

Technical ceramics are characterised by excellent mechanical strength and hardness, and are widely used in extreme wear applications.