ALUMINA CERAMIC

Aluminium oxide (Al₂O₃) is the most popular technical ceramic in use today, offering unbeaten price-to-performance characteristics in a wide range of application areas. The appeal of alumina largely stems from its extreme versatility. Ceramic engineers can finely moderate both the chemical and thermomechanical properties of alumina ceramics using a choice of additives and bonding techniques. Different types of alumina are consequently characterized mainly by purity.

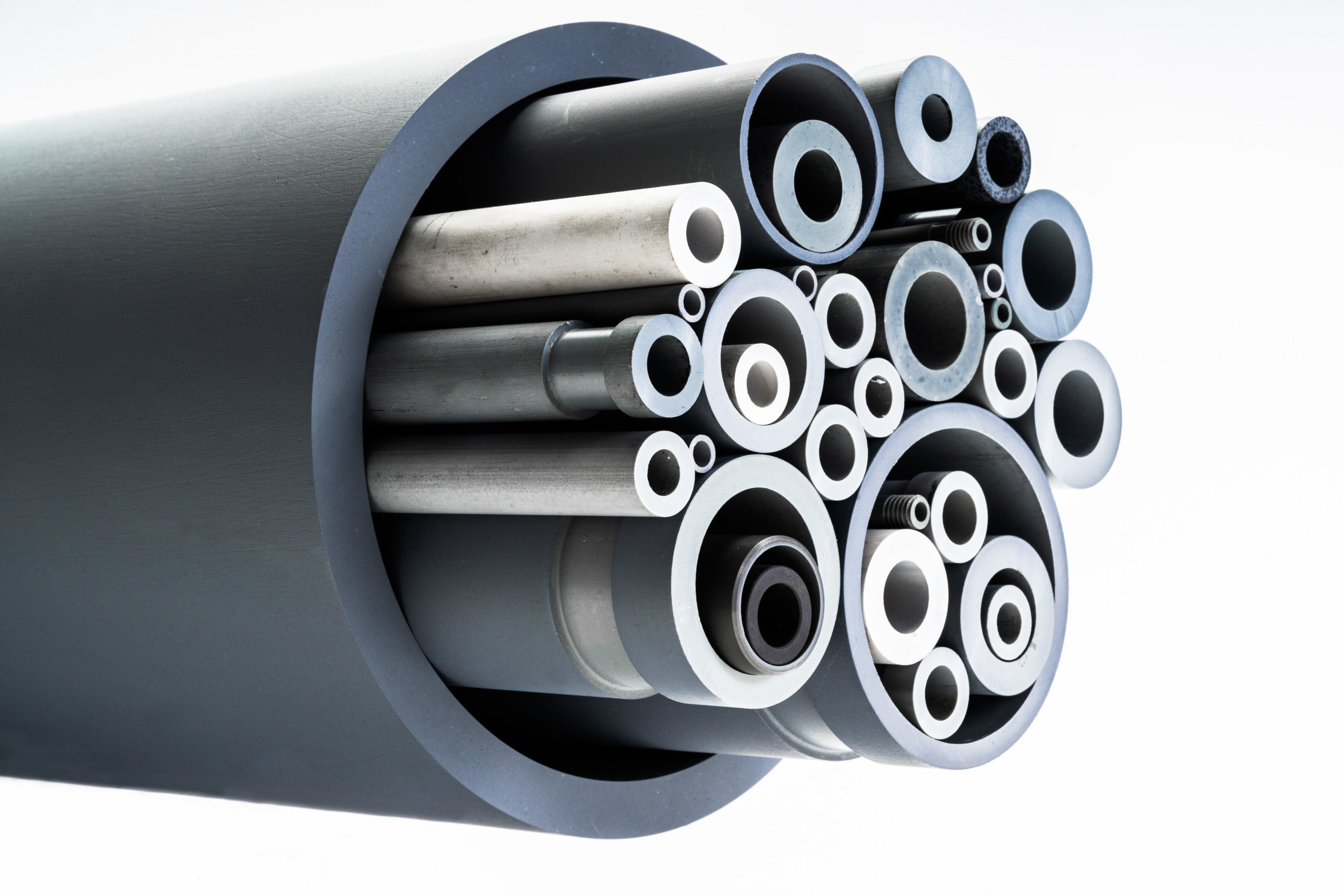

International Syalons is one of the UK’s foremost technical ceramics suppliers and manufacturers, offering a suite of high-purity alumina ceramics. Purity in this context refers to the concentration of Al₂O₃ in the finished part, with greater purities translating to superior corrosion-resistant and wear-resistant behaviour. Our alumina products are based on 95 – 99.9% pure aluminium oxide in a fully densified configuration. Typical performance characteristics include:

- Good flexural strength (500 MPa)

- High density (3.95 g/cc)

- Excellent electrical resistivity (1050 Ω cm)

- Extremely high hardness (1800 Kg/mm2)

- High operating temperature capabilities (max 1700°C)

Browse our alumina products below for full specifications and datasheets.

Aloxalon 96

Aloxalon 96 is fully dense and suitable for wear and corrosion resistant applications. The table below lists typical mechanical, thermal and electrical property data for Aluminon 96.

Download the Aloxalon 96 Property Datasheet

Aloxalon 96 - Physical Property Data

Aloxalon 995

Aloxalon 995 is fully dense and has excellent corrosion resistance. In addition, it has excellent thermal stability up to 1700°C and can be used as noble metal thermocouple protection tubes. The table below lists typical mechanical, thermal and electrical property data for Aloxalon 995.

Download the Aloxalon 995 Property Datasheet

Aloxalon 995 - Physical Property Data

Aloxalon 999

Aloxalon 999 is a very high purity material with excellent mechanical, thermal and corrosion resistant properties. It is the most stable of our aluminas and is suitable for severe wear and corrosion applications. The table below lists typical mechanical, thermal and electrical property data for Aloxalon 999.

Download the Aloxalon 999 Property Datasheet

Aloxalon 999 - Physical Property Data

The successful integration of advanced technical ceramics into engineering systems requires close collaboration between you, the end-user, and ourselves, the material manufacturer. Please call +44(0)191 2951010 or email for an initial consultation with our technical sales team, or send us a Request for Quote.

In addition, see our resources section for guides on designing with ceramics and more property data comparing alumina with other engineering ceramics. For a comparison of the physical properties of all our materials see our Material Properties Datasheet.

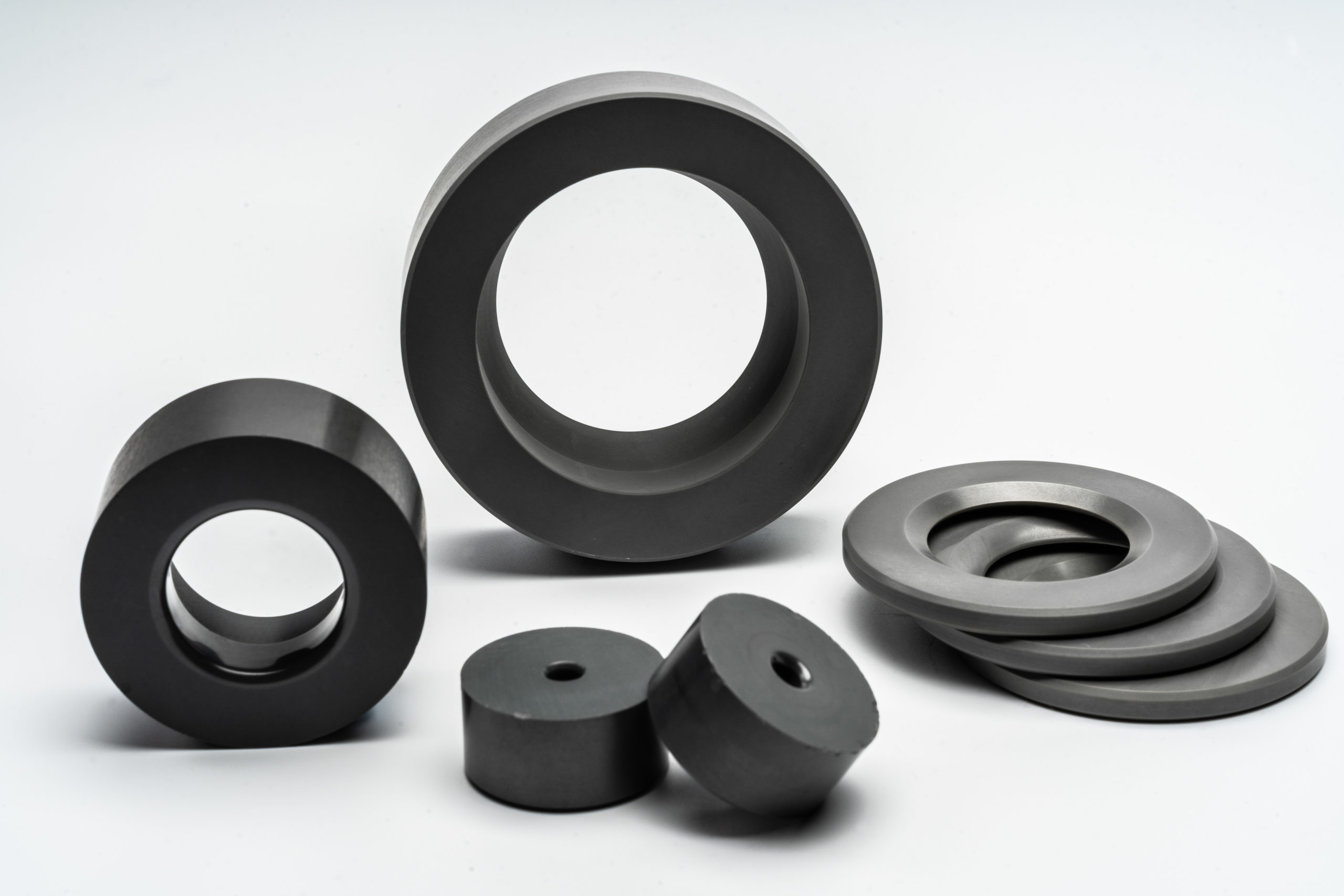

International Syalons manufacture a range of silicon nitride and sialon advanced ceramic thermocouple protection sheaths for use in the aluminium and molten metal handling industries.

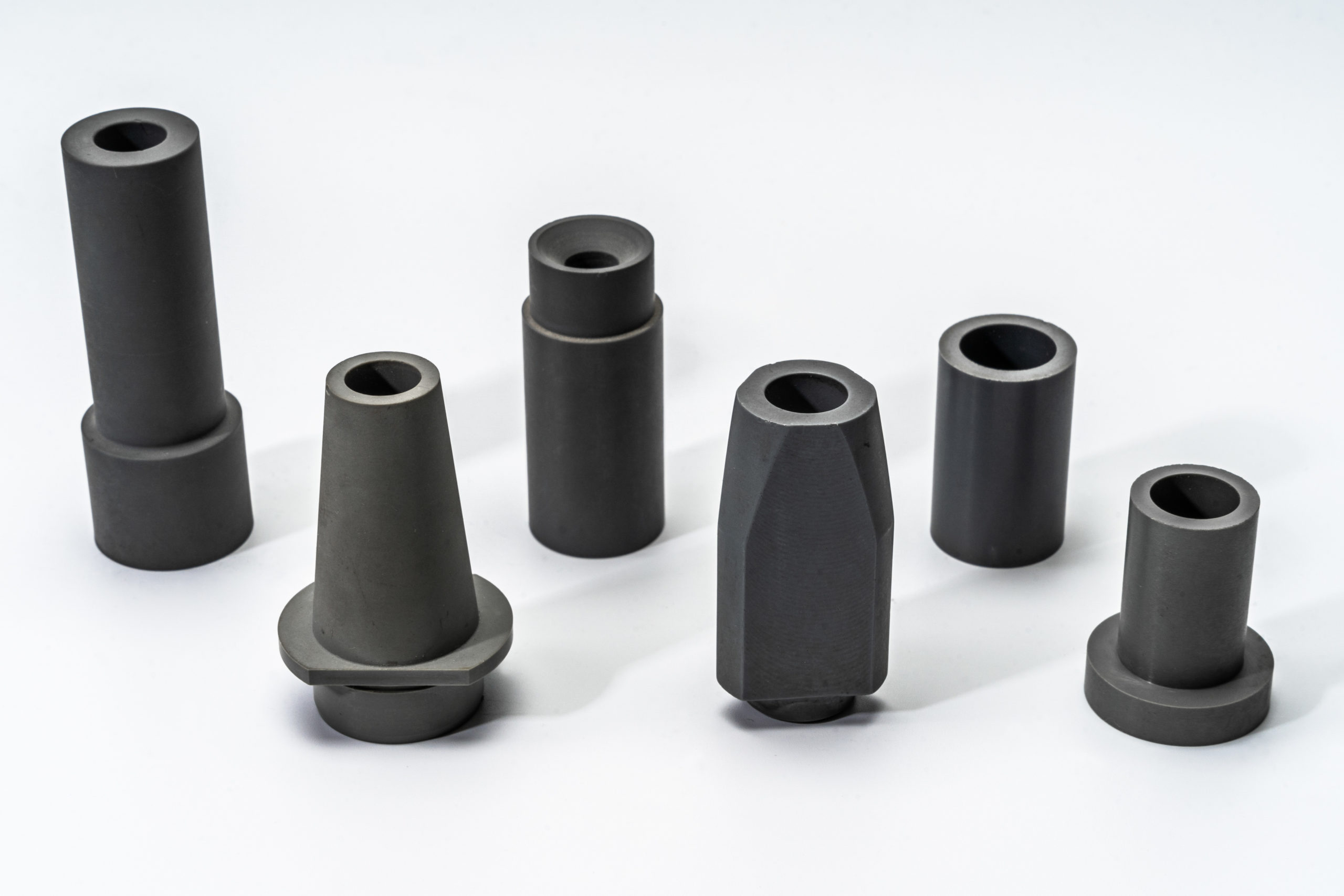

Syalon is the preferred choice when looking to improve nozzle wear resistance, outperforming many competitive materials such as alumina and tungsten carbide.

International Syalons manufacture a range of bespoke silicon nitride dies, which are used for high volume extrusion and drawing of copper and non-ferrous tube, rod, and wire products.