Sialon ceramics based on high-strength silicon nitride were engineered as a cost-effective solution to some of the most demanding thermal processing and mechanical industrial environments. A tetrahedral arrangement of silicon—nitrogen bonds substituted with the addition of aluminium and oxygen provides exceptional resistance to varied thermodynamic stresses, with enhanced resistance to corrosive attack. These properties are supplemented with high material strengths and physical integrity under applied forces.

Silicon nitride ceramics offer high ultimate tensile strengths (UTS) to resist elongation, and outstanding flexural strengths to withstand yielding or rupture at elevated transverse stresses. Flexural strength is also known as the modulus of rupture. This blog post will explore the modulus of rupture of silicon nitride ceramics in more detail:

What is the Modulus of Rupture?

A material’s modulus of rupture (MOR) differs from its tensile strength in that UTS defines the maximum stress a material can withstand before severe deformation due to stretching. The modulus of rupture meanwhile refers to the point at which a material cross-section will break due to bending.

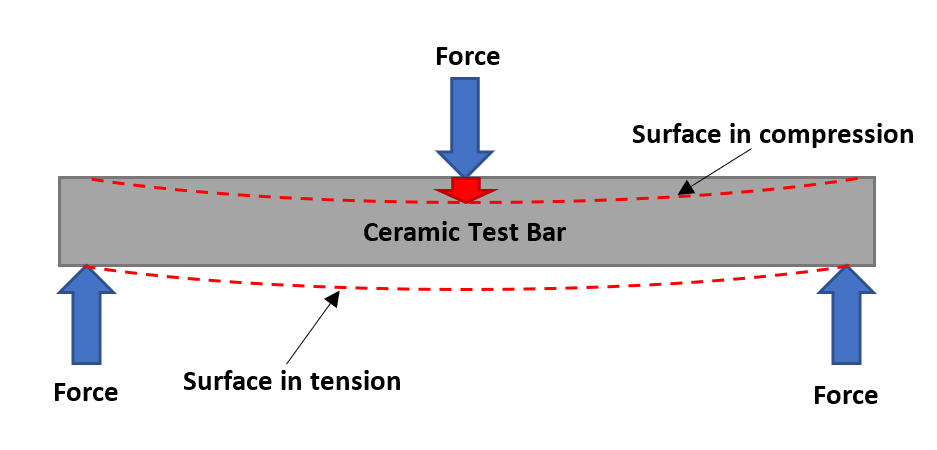

The two properties are intrinsically linked. When a component or test piece is tested under three-point-bend (3PB) conditions the concave surface is subject to compression while the convex surface elongates under tension as shown in the schematic drawing below, eventually leading to rupture or failure of the component.

Modulus of rupture is generally expressed in mega-pascals of applied force (MPa) and can be determined from the axial load (F) at the point of fracture, and the cross-section of the material.

Importance of Modulus of Rupture

Modulus of rupture is critical for characterising a material’s structural capacities in response to high axial loads. This is vital for load-bearing components required to withstand varied thermodynamic stresses in severe operating conditions. Silicon nitride ceramics for refractory environments typically exhibit high moduli of rupture to resist fracture due to bending and ensure long component services lives for even the most demanding applications.

- To learn more about the mechanical properties of technical ceramics, read The Young’s Modulus of Silicon Nitride Ceramics

Silicon Nitride and the Modulus of Rupture

Silicon nitride ceramics represent an outstanding range of flexural strengths suitable for distinct application requirements. Technical silicon carbide displays a 3-point modulus of rupture of 450 MPa, while silicon nitride-based ceramics display moduli of rupture ranging from 500 – 945 MPa.

- Syalon 101: MOR = 945 MPa at 20°C, and 700 MPa at 1000°C.

- Syalon 110: MOR = 500 MPa at 20°C, and 400 MPa at 1000°C.

- Syalon 050: MOR = 800 MPa at 20°C, and 750 MPa at 1000°C.

- Syalon 501: MOR = 825 MPa at 20°C.

Silicon Nitride Ceramics from International Syalons

International Syalons designs and engineers cutting-edge technical ceramics and refractory materials to the highest standard of certification. Our advanced silicon nitride ceramics are suitable for application in chemical processing, ferrous and non-ferrous metal handling, and oil and gas recovery applications.

- International Syalons provides a proprietary product known as Zircalon 30 – A New Grade of Fracture-Resistant Zirconia for Welding Applications. Read more to learn how we generated a new material with an MOR = 1000 MPa at 20°C.

If you would like any more information about the range of silicon nitride ceramics available from International Syalons, please do not hesitate to contact us.