SILICON NITRIDE / SIALON CERAMIC

Silicon nitride (Si₃N₄) excels in harsh working environments, offering some of the most attractive thermomechanical properties among oxide and non-oxide ceramics. The material property and design limitations of reaction-bonded or hot-pressed silicon nitride ceramics have been overcome through the development of sialon; novel silicon nitride-based ceramic ‘alloys’ that dramatically reduce manufacturing costs whilst offering increased mechanical performance characteristics.

International Syalons is the UK’s leading supplier of sialon and silicon nitride-based ceramic components. Our unique technical grades are strong and extremely durable, competing with traditional engineered materials in terms of mechanical and thermal performance. This comes thanks to their unique interlocking microstructures and high strength atomic bonding. The benefits of this robust structure include:

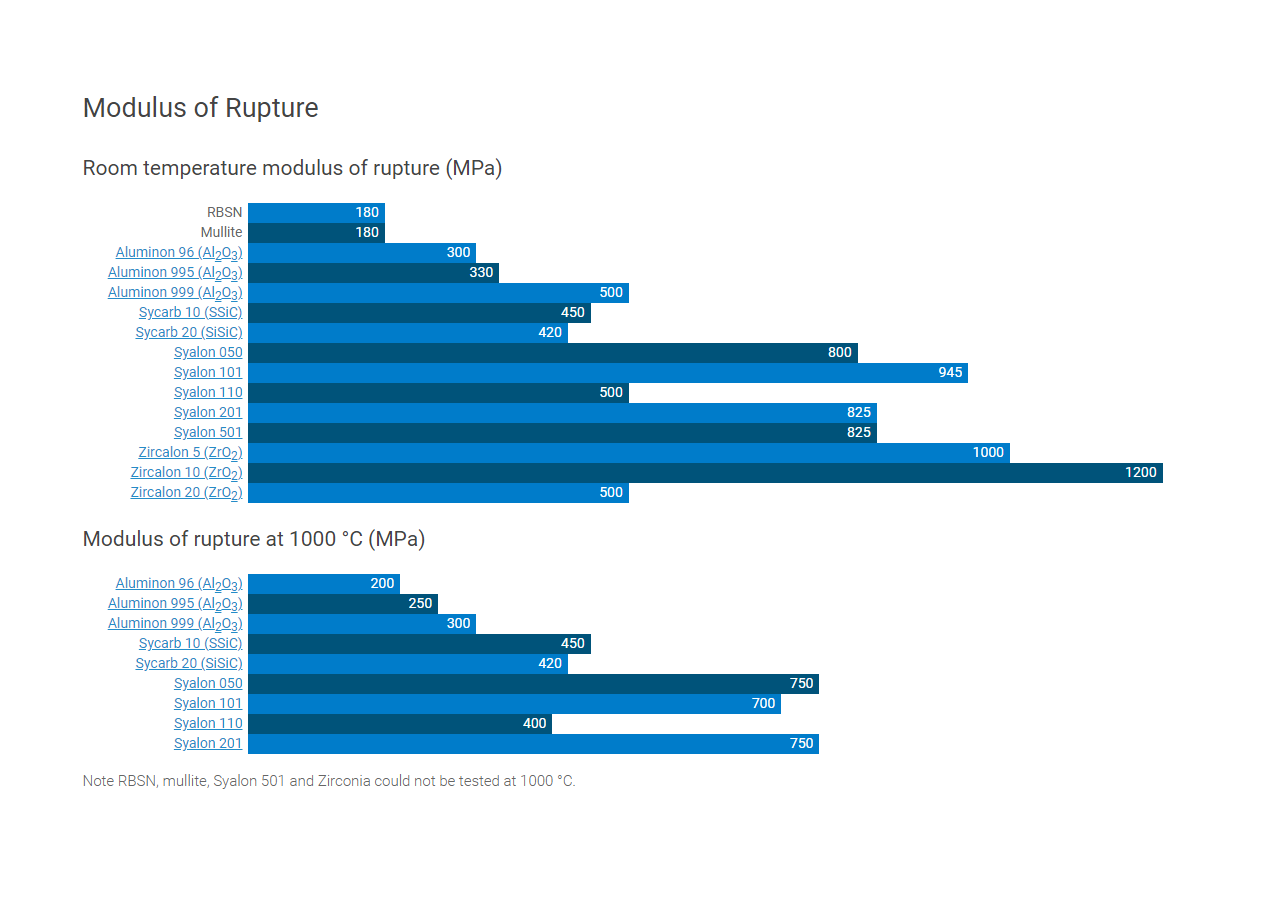

- Excellent flexural strength (945 MPa)

- Outstanding thermal shock resistance (ΔT = 900°C)

- High operating temperature capabilities (max 1450°C)

- High fracture toughness (7.7 MPa m½)

- Very low thermal expansion coefficient (3x10-6 K-1)

The material property and design limitations of reaction-bonded or hot-pressed silicon nitride ceramics have been overcome through the development of sialon; novel silicon nitride-based ceramic ‘alloys’ that dramatically reduce manufacturing costs whilst offering increased mechanical performance characteristics.

Achieving a high density silicon nitride component used to be an extremely costly process. At International Syalons, we can produce fully-dense, defect free sialon ceramics via pressureless and high-pressure sintering; a cheaper and easier process than hot-pressing or reaction bonding of silicon nitride. Through 40 years’ of concerted research and development, we have refined this process to create five distinct sialon ceramics that address specific design and performance areas in challenging engineering environments across a wide range of industries.

Browse our sialon products below to find out more about their individual specifications and suitability to your applications. Or, Please call +44(0)191 2951010 or email for an initial consultation with our technical sales team or send us a Request for Quote.

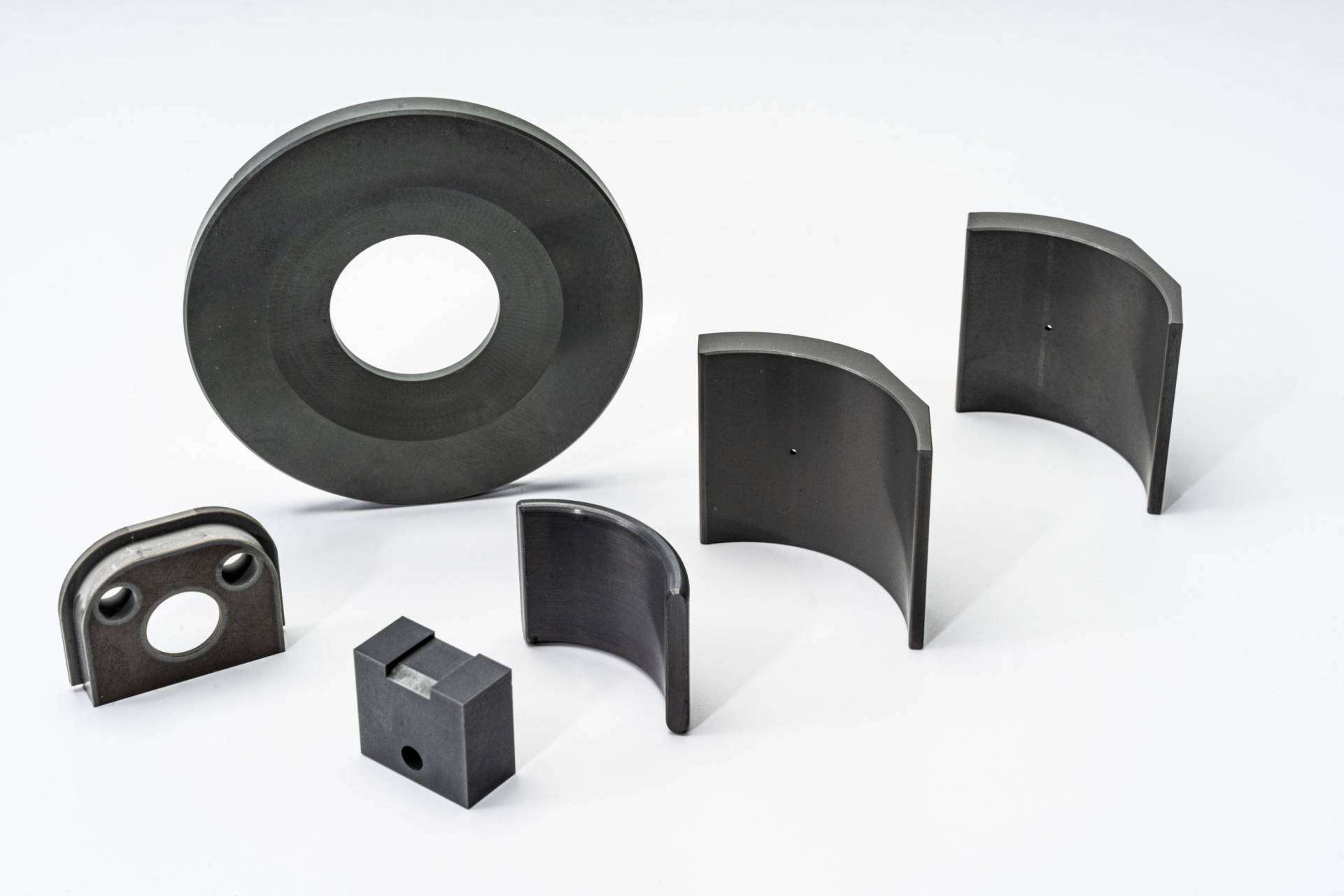

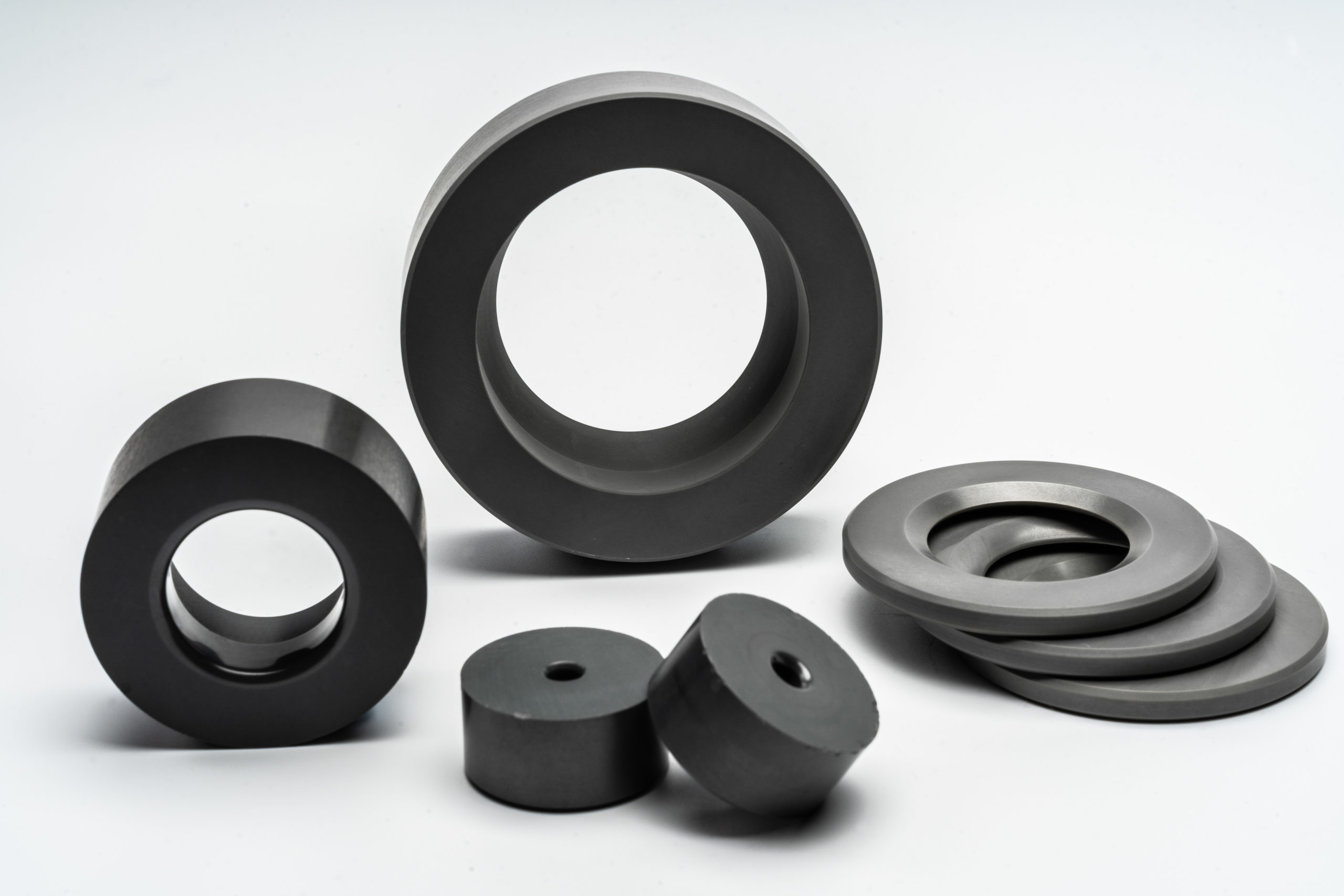

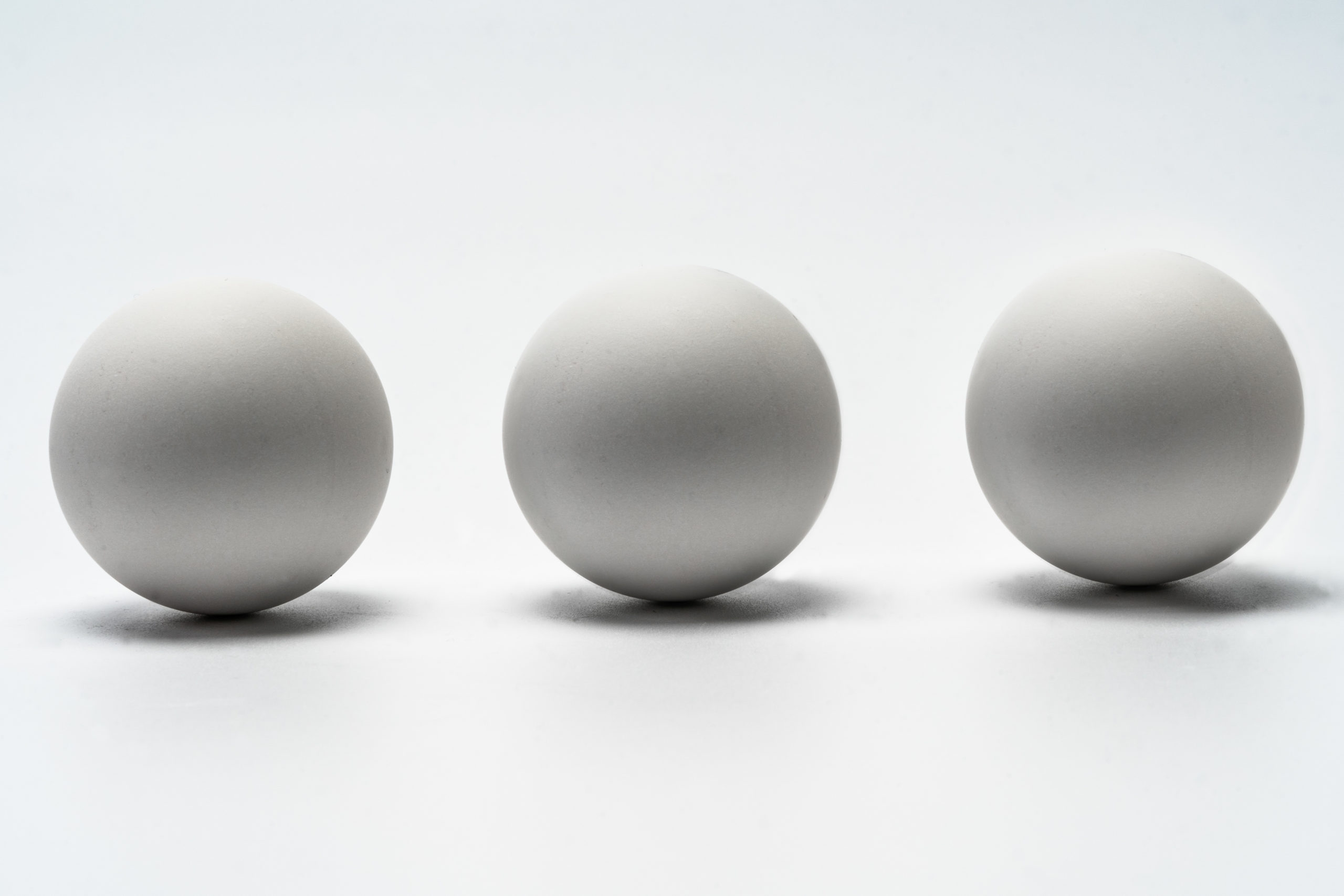

Syalon 101 is a grade of sialon which offers the best general combination of properties. These include high strength, hardness and toughness as well as excellent corrosion resistance. Typical applications of Syalon 101 include thermocouple protection sheaths, milling media and hydrocyclones.

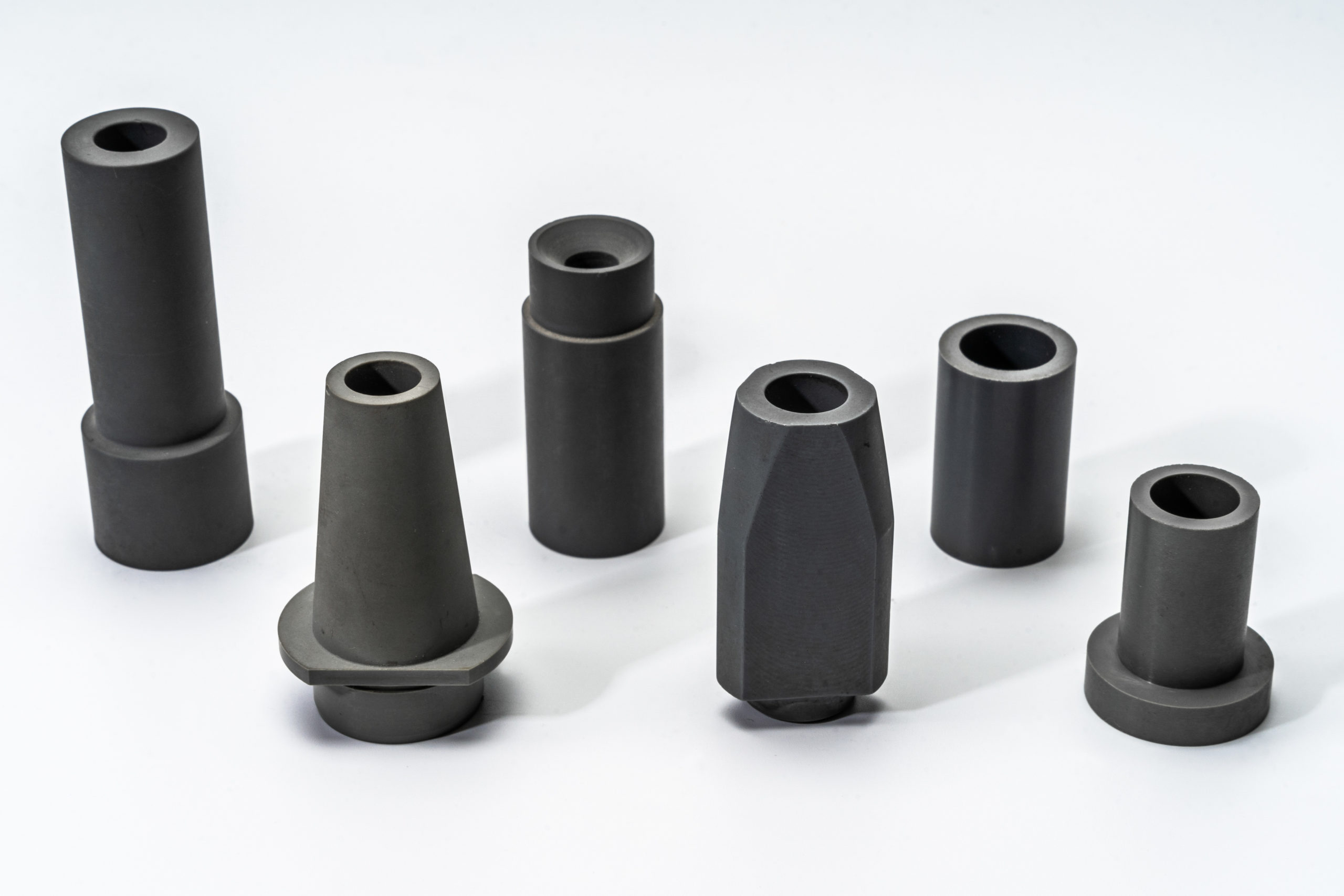

Syalon 050 is suited to wear and high temperature applications. It has extreme hardness combined with high strength and can be used in applications up to 1400°C in air. Typical applications of Syalon 050 include shot blast nozzles and thermocouple protection sheaths for high temperature alloys.

Syalon 110 is a composite grade of sialon originally developed as a break ring for the horizontal continuous casting of steel. As such its properties include improved corrosion resistance to steel over other silicon nitride grades, outstanding thermal shock resistance and usable up to temperatures in excess of 1450°C.

Syalon 501 is a composite grade silicon nitride based sialon ceramic developed to provide an electrically conducting advanced ceramic with the traditional silicon nitride properties of high strength, toughness and hardness. This allows Syalon 501 to be electro–discharge machined into more complex shapes than other types of silicon nitride without the need for expensive diamond grinding and any major loss in it's fundamental properties.

Syalon 201 is a β-sialon, similar to Syalon 101 but with better retention of strength up to 1350°C in air. Typical applications of Syalon 201 include molten metal handling applications where high temperature strength is required or high temperature wear applications where hot hardness is required.

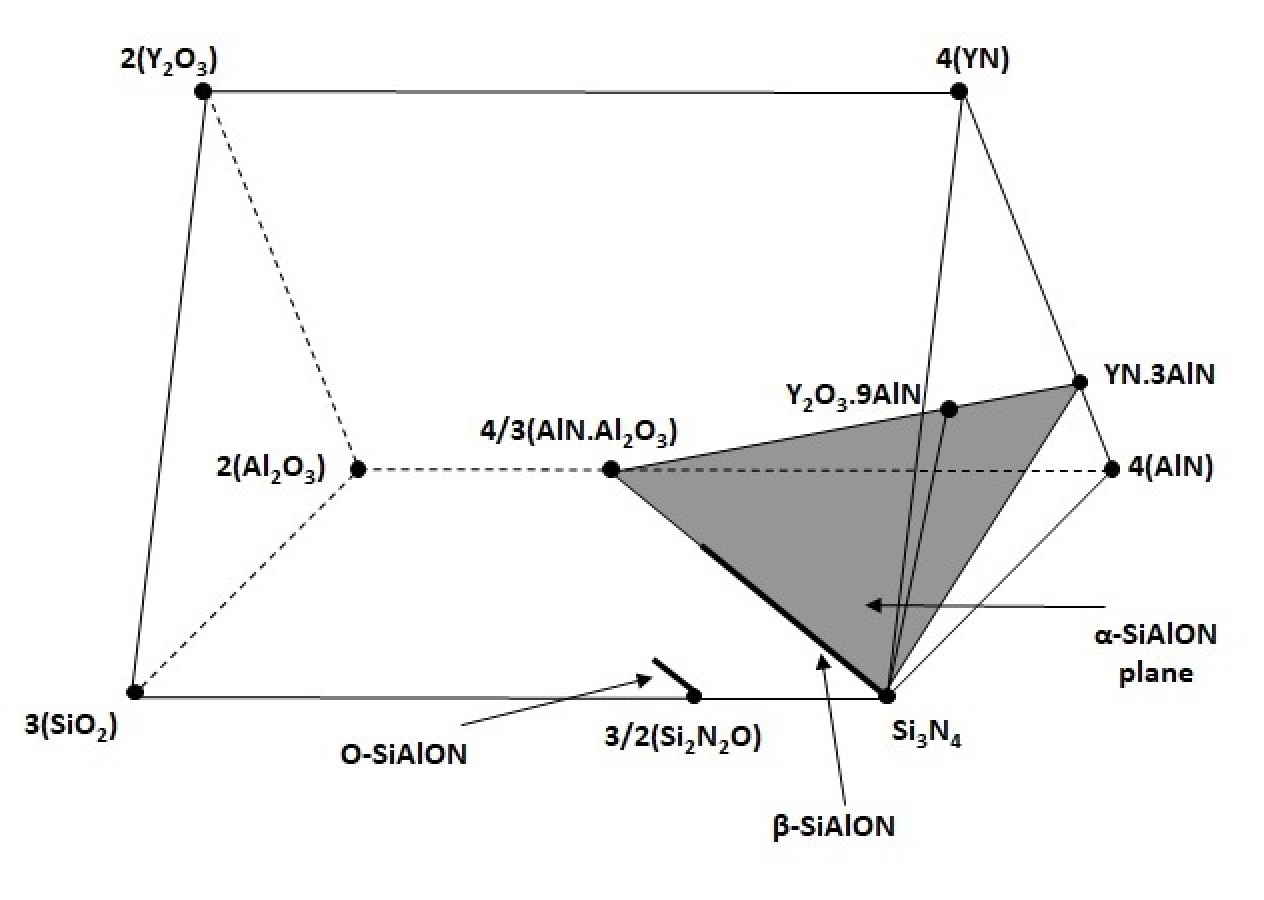

What are sialon ceramics?

Technical ceramic property comparison table

Sialon and zirconia provide the high temperature strength and non-wetting properties necessary for metal casting, extruding, and welding.

Technical ceramics are characterised by excellent mechanical strength and hardness, and are widely used in extreme wear applications.

Silicon nitride offers excellent corrosion and thermal resistance and are ideal materials for use in the chemical and process industries.