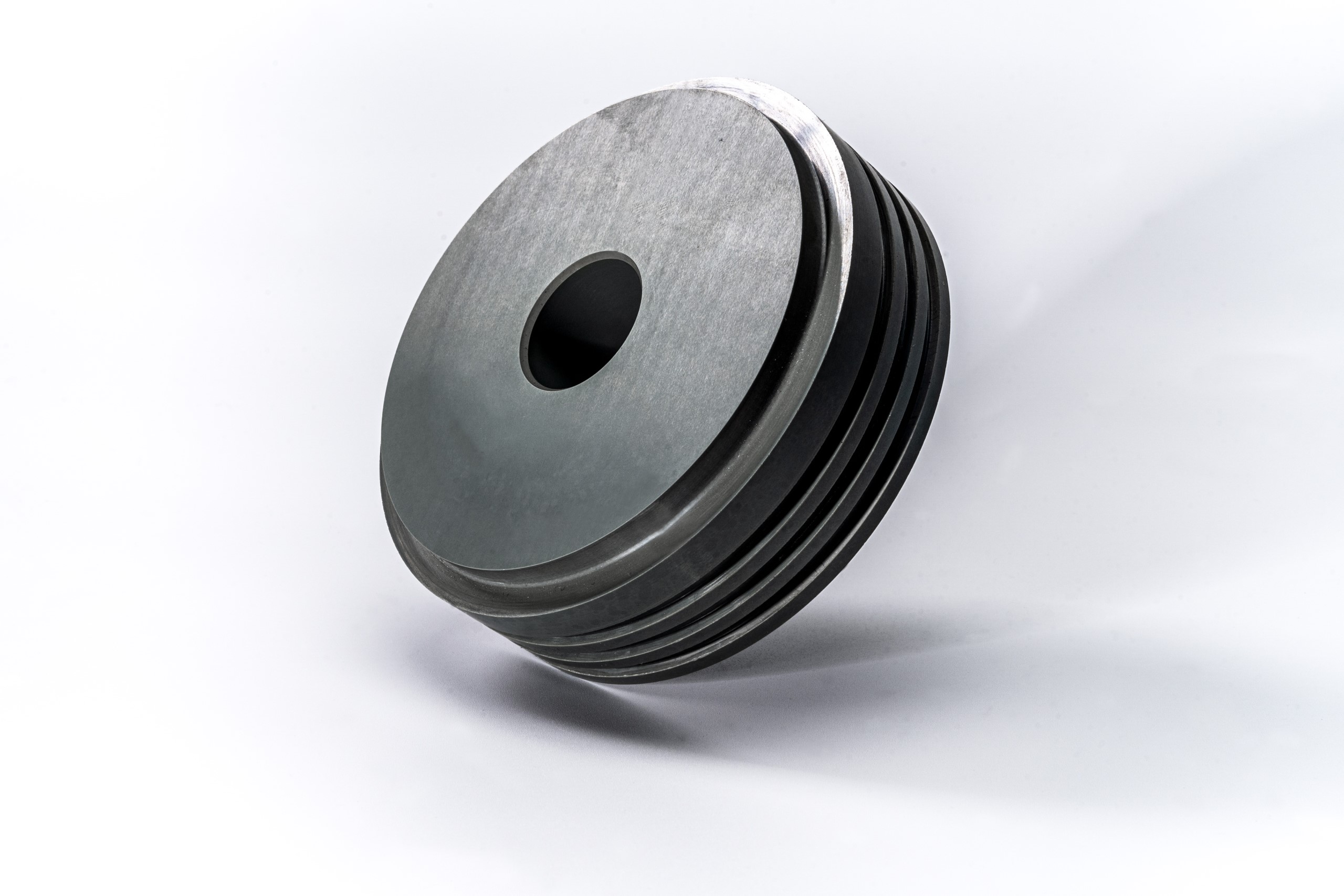

CERAMIC HEATER AND RISER TUBES

Ceramic heater tubes are the go-to solution for protecting heating elements in aluminium and other non-ferrous foundry applications. Designed to withstand direct contact with molten metals, heater and riser tubes must be intrinsically corrosion resistant, demonstrating excellent thermal properties and mechanical strength. Selecting the right tube material is essential for preserving the long service of elements used in the heating module. Sialon ceramic materials are the gold standard for ceramic immersion heater and riser tubes in foundry settings.

Syalon 101 is an outstanding engineering-grade material based on the unique chemistry of silicon nitride. First in a novel class of technical ceramics known as sialons, Syalon 101 embodies the ideal thermal and mechanical properties for ceramic heater tubes – including immersion and induction heaters. Heaters of this sort require a careful balance of thermal conductivity and resistance to mitigate thermal losses and maintain optimal process efficiency. Syalon 101 excels here too.

Other key enabling features include:

- Outstanding thermal shock resistance

- Higher density and strength than conventional ceramics

- Excellent corrosion resistance to non-ferrous metals (aluminium, zinc, etc.)

- Non-wetting behaviour resists the build-up of dross

- Offers long-life performance resulting in significant cost-savings

Our range of ceramic heater and ceramic riser tubes is extremely diverse, including both closed and angled open-end options. View the table below for a selection of our standard sizes. We are also keen to collaborate with new partners looking for novel solutions. If you are curious about how Syalon 101 ceramic heater tubes could help you optimise your foundry processes, enquire today.

For details on using our sialon tubes, please download our User Guide.

Standard Sizes - Heater and Riser Tubes

Download our Sialon Ceramics for Aluminium Casting for more details.

For more information on non-ferrous molten metal handling applications of silicon nitride and sialon fine ceramics please download our Molten Metal Handling Applications Guide.

Syalon 101 is a grade of sialon which offers the best general combination of properties. These include high strength, hardness and toughness as well as excellent corrosion resistance.

Syalon 050 is suited to wear and high temperature applications. It has extreme hardness combined with high strength and can be used in applications up to 1400°C in air.

Syalon 110 is silicon nitride-boron nitride composite, offering high temperature corrosion resistance in challenging molten metal handling applications.