TECHNICAL CERAMIC SPECIALISTS

SILICON NITRIDE AND SIALON ADVANCED CERAMICS

CERAMIC ENGINEERING SOLUTIONS

SUPPORTING INDUSTRY WITH NOVEL TECHNOLOGY

HIGH TEMPERATURE STRENGTH

BESPOKE PRODUCTS FOR THERMAL PROCESSING

CONFIDENCE IN QUALITY

INDUSTRIAL EFFICIENCY AND SUSTAINABILITY

PROGRESS THROUGH INNOVATION

OVER 40 YEARS' OF TECHNICAL CERAMIC DEVELOPMENT

Advanced Ceramic Solutions for Extreme Environments

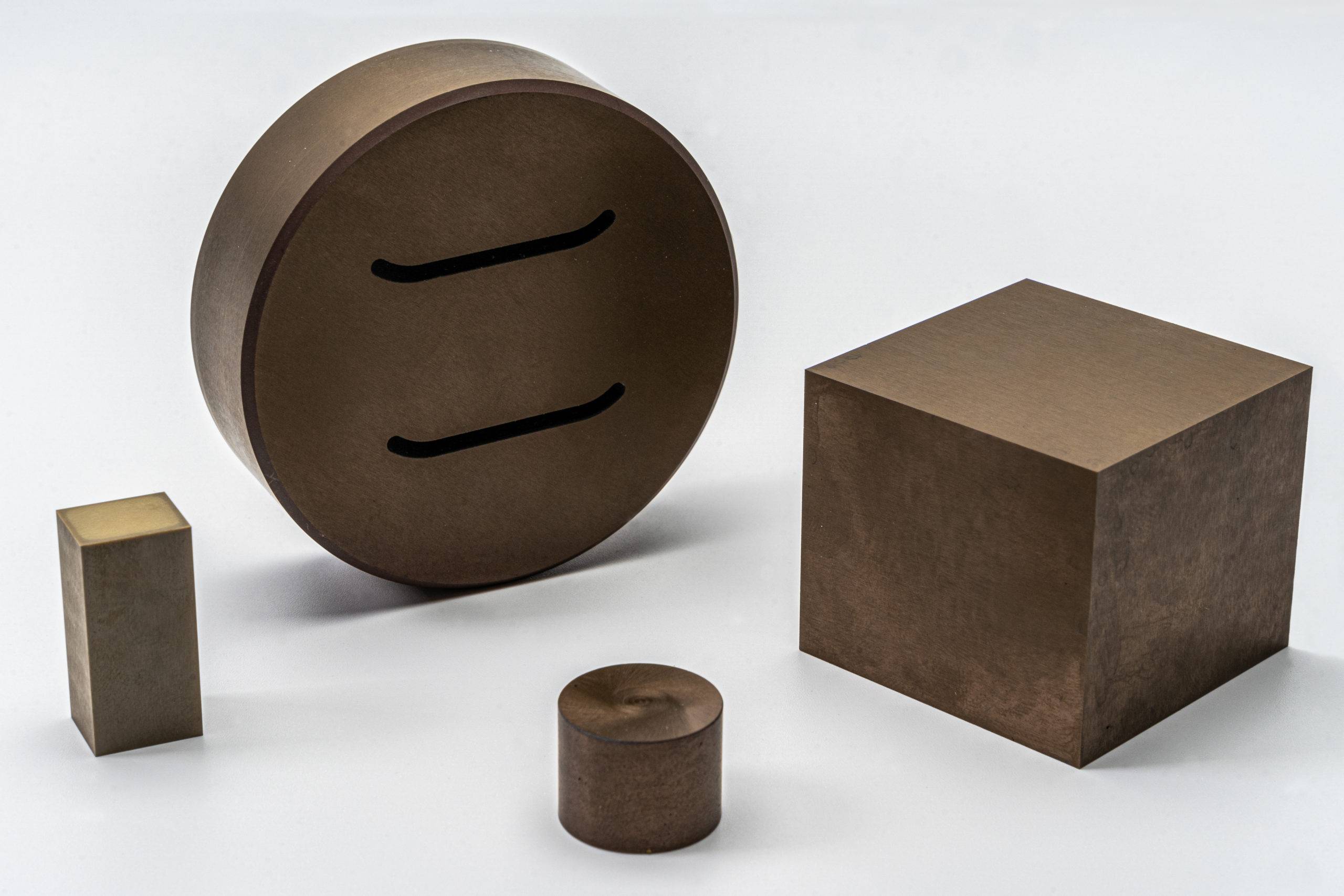

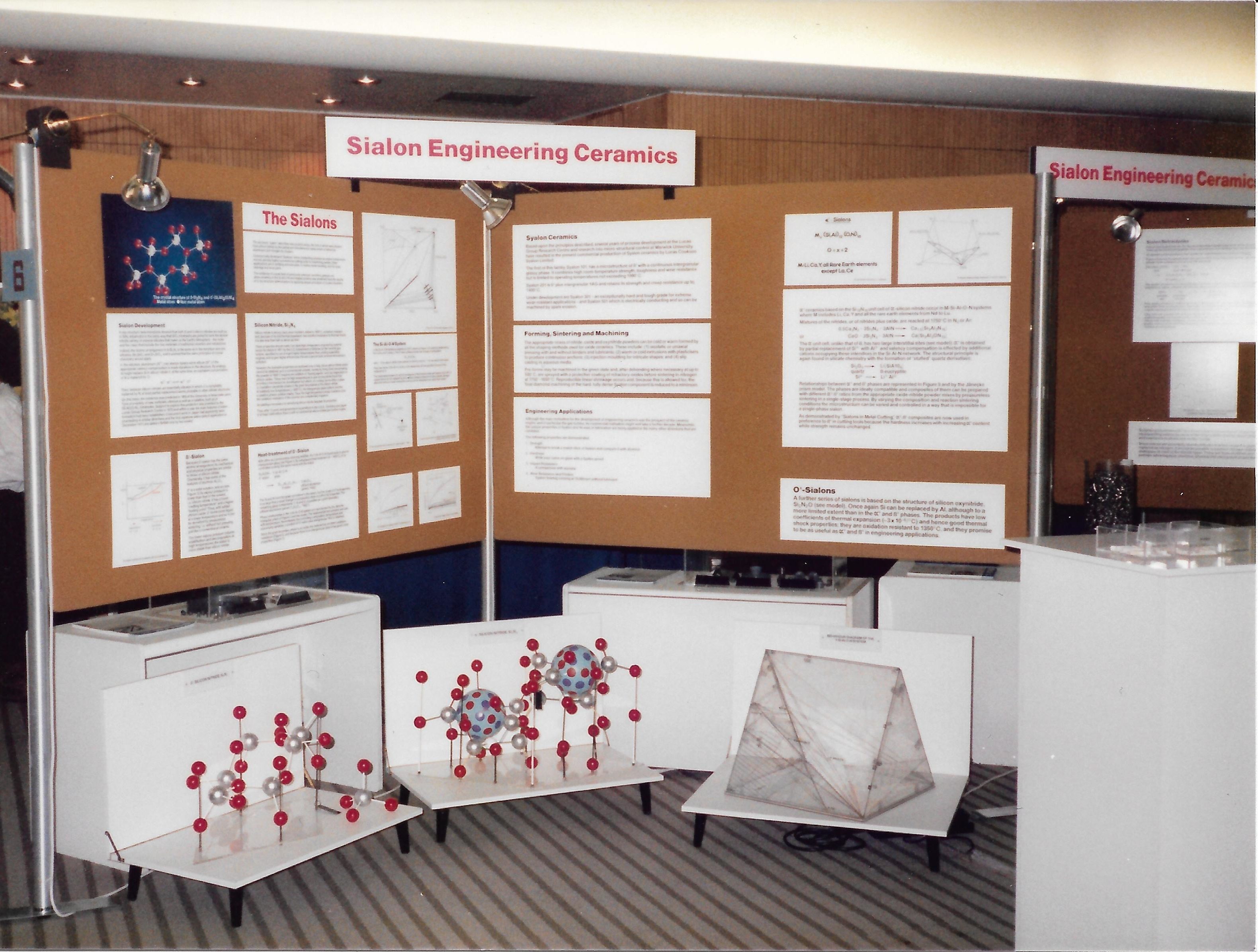

With nearly forty years experience in the production and development of advanced engineering ceramics, International Syalons (Newcastle) Ltd. are experts in the field. We are based near Newcastle upon Tyne in the North East of England and are the UK’s leading manufacturer of sialon and silicon nitride based technical ceramic products and powders.

Syalons are advanced silicon nitride based technical ceramics and are amongst the strongest and most durable ceramic materials known. Their outstanding properties allow them to compete with other engineering ceramics and refractories such as zirconia (ZrO₂), alumina (Al₂O₃) and silicon carbide (SiC) in many diverse industrial applications. Syalons, also known as SiAlONs, were the world’s first commercially available advanced ceramic alloys.

In addition, we can offer a range of advanced technical ceramic solutions such as alumina, zirconia and silicon carbide and can offer a complete solution to your advanced ceramic requirement. Please call +44(0)191 2951010 or email for an initial consultation with our technical sales team or send us a Request for Quote.

YOUR CHALLENGES - SOLVED

MATERIAL PERFORMANCE

Abrasive Wear

MATERIAL PERFORMANCE

Chemical resistance

PROCESS EFFICIENCY

METAL ADHESION

COST SAVINGS

QUALITY ISSUES

MATERIAL PERFORMANCE

CRACKING

YOUR CHALLENGES - SOLVED

MATERIAL PERFORMANCE

THERMAL SHOCK

COST SAVINGS

MAINTENANCE COSTS

MATERIAL PERFORMANCE

CORROSION

DESIGN SOLUTION

FATIGUE

DESIGN SOLUTION

CREEP

YOUR CHALLENGES - SOLVED

PROCESS EFFICIENCY

CONTAMINATION

COST SAVINGS

SUPPLY CHAIN ISSUES

MATERIAL PERFORMANCE

OXIDATION

DESIGN SOLUTION

WEIGHT SAVINGS

MATERIAL PERFORMANCE

EROSION

Latest News

Developing and Implementing a Standardised Approach to Testing Silicon Nitride Based Ceramics

December 12, 2024

Choosing corrosion-resistant ceramics for hybrid loads (Chemical, mechanical & thermal)

January 15, 2026

How does the chlorine corrosion of graphite compare to technical ceramics?

January 5, 2026

How can EDM-machined ceramic extrusion dies help prevent cross-contamination in industry?

December 8, 2025

Choosing chemical-resistant materials for chlorine-based industrial conditions

October 22, 2025

Advanced Ceramic Solutions

Blog Highlights

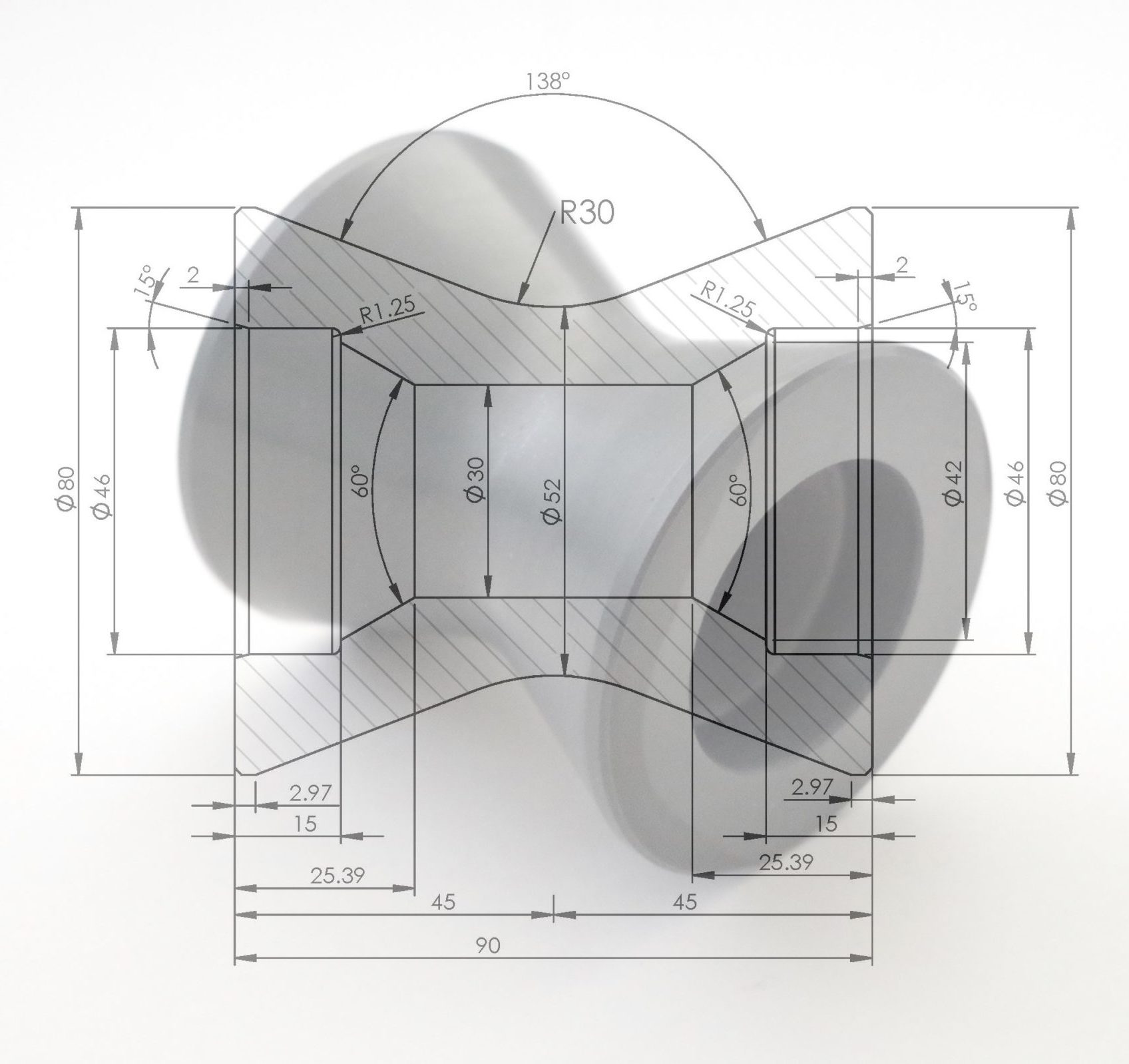

Designing with Technical Ceramics

Designing with Technical Ceramics

Technical ceramics represent the cutting-edge of industrial materials…

The History of SiAlON Ceramics

In the 1970s, independent studies in Japan and at Newcastle…

Silicon Nitride and Aluminium

The extreme requirements of aluminium production require durable…

Featured Materials

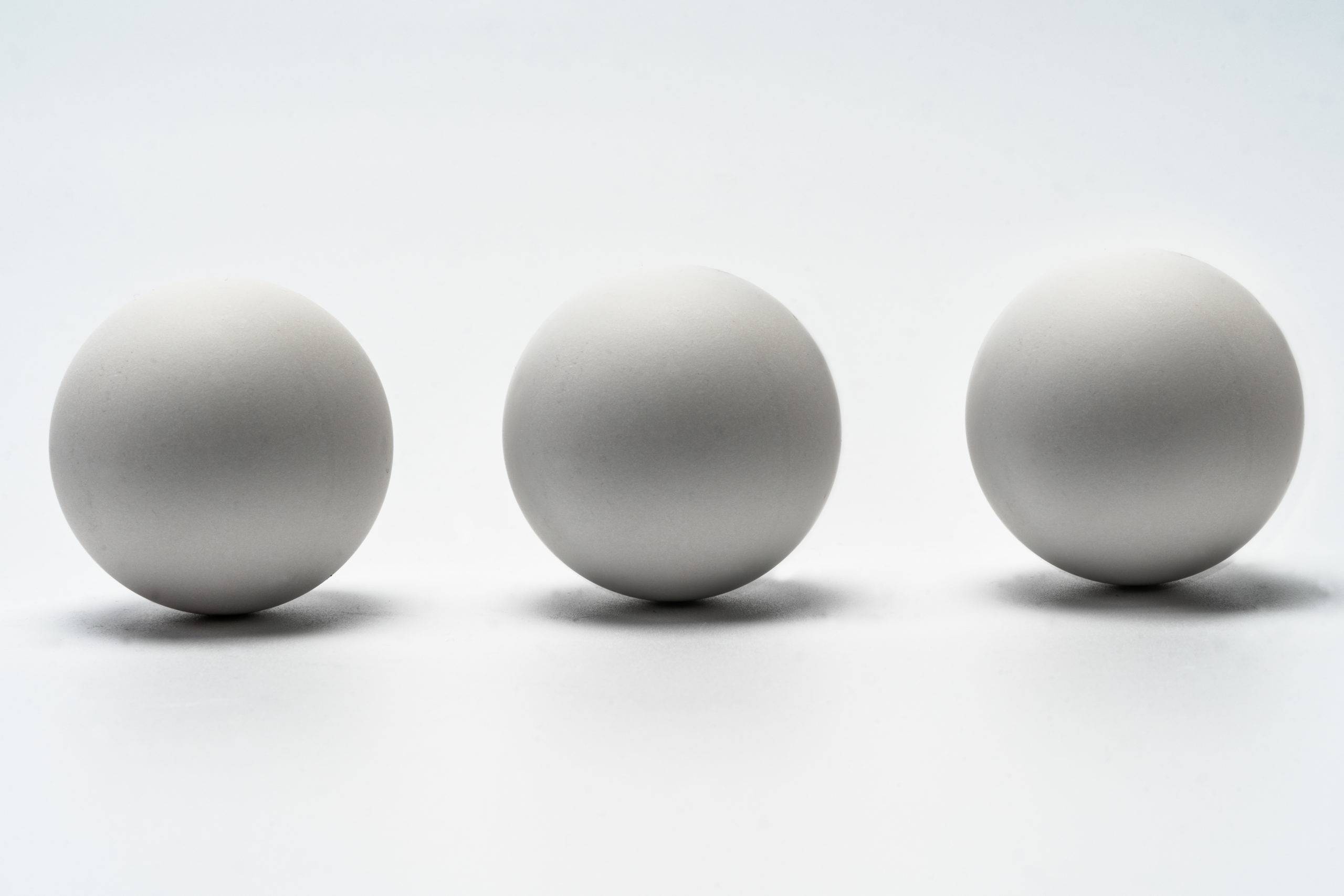

An advanced silicon nitride (Si3N4) ceramic offering outstanding mechanical strength, thermal shock resistance and corrosion resistant properties.

A high purity yttria-stabilised zirconia (YSZ) ceramic with excellent fracture toughness, hardness and high temperature resistance.

An advanced silicon nitride (Si3N4) ceramic offering outstanding wear, corrosion, oxidation and high temperature creep resistant properties.