Aluminium (Al) is the second-most industrially consumed metal worldwide. The global aluminium market produces over 50-million tons of aluminium each year, chiefly through the refinement of bauxite ore at sites in North America, Russia, China, and more. At these sites, industrially viable alumina (Al2O3) is refined from bauxite through the Bayer process, which involves crushing and heating the metal in a pressure vessel with a sodium hydroxide solution at temperatures of up to 200°C. The extracted alumina is then smelted at refractory temperatures of up to 980°C in molten cryolite (Na3AlF6), to produce pure aluminium for use in an enormous range of commercial and industrial sectors.

The extreme requirements of aluminium production require durable, high-thermal materials with excellent corrosion resistance and low aluminium penetration. Refractory components such as thermocouple protection sheaths, riser and heater tubes, and extrusion die casts must therefore perform consistently and efficiently to maintain optimal production levels in an industry with such enormous global demand.

Advanced silicon nitrides (Si3N4), known as sialons (Si-Al-O-N), are perfectly equipped to handle such stringent specifications. These refractory ceramics can be produced in a range of shapes that show retention of strength up to 1450°C, with a very low wettability to molten aluminium and outstanding thermal shock resistance guaranteeing a long service life of sialon in the aluminium industry.

Sialon for Molten Aluminium Handling

International Syalons produces three primary sialon components for molten metal handling, which are pervasively used in the aluminium industry:

- Thermocouple Protection Sheaths: Advanced ceramic tubes capable of reliably and minutely monitoring the temperature of aluminium foundries, with a choice of Syalon materials offering exceptional physical properties at temperatures up to 1200°C, and 1400°C;

- Riser & Heater Tubes: High strength sialon ceramic cylindrical heaters for heating the melt in aluminium processing. These can be built to a range of dimensions;

- Level Sensors: Used in the extrusion die casting of molten metals, including aluminium, into ingots or their final fit-for-purpose shapes. Temperature applications of sialon level sensors range up to 800°C, allowing for accurate monitoring of molten aluminium in pressurized cavities.

The durable, repeated use of sialon components for aluminium production is instrumental in recycling processes. Aluminium exhibits excellent corrosion resistance, allowing for technically infinite recycling properties. Recycled aluminium is typically smelted into ingots, as per the ordinary aluminium refractory process. These are then compounded into foundry alloys, and shaped to an array of potential purposes using extrusion die apparatuses.

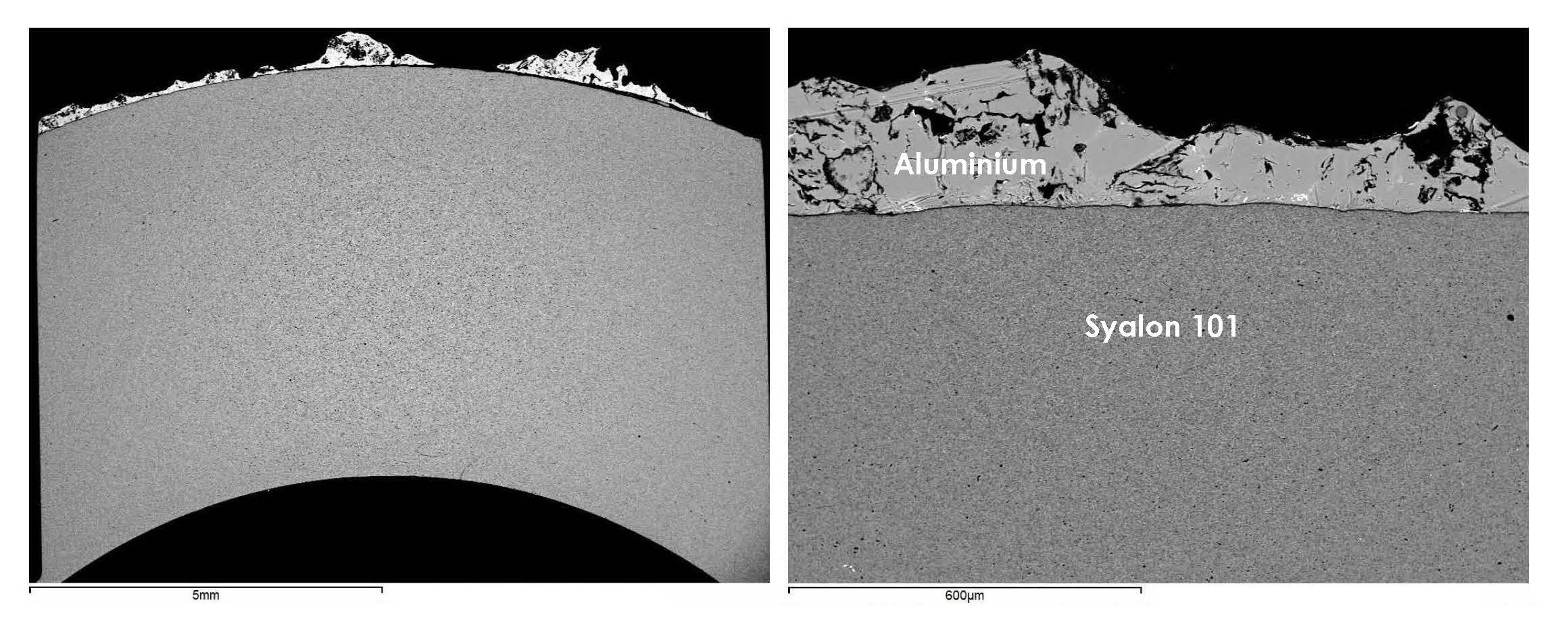

Cross-section of Syalon 101 thermocouple sheath after use in aluminium production, showing zero porosity or ingress of molten metal into the ceramic

Sialon for Aluminium Forming Applications

The cost-efficiency and high durability of International Syalons’ materials offer incredible benefits beyond the refining, smelting, and handling of molten aluminium. With excellent chemical stability and high thermal properties, sialon ceramics are also instrumental in the welding and shaping of aluminium alloys. We produce a range of sialon ceramics fit for such purposes, with products including:

- Weld Location Pins: Used in the welding of cage nuts for automotive assembly lines, with vastly improved efficiency over previously used steel nuts for vehicle operations;

- Welding Jigs & Fixtures: Used in orbital welding techniques to fuse curved components to one another; typically employed in the aerospace industry for the formation of aircraft fuselages.

International Syalons’ Materials for the Aluminium Industry

International Syalons has decades of experience in the development and production of advanced sialon ceramics for use in refractory industries, including the aluminium industry. These materials have shown improved mechanical properties over traditional materials implemented in industrial environments, with a choice of advanced silicon nitride grades with varying chemical properties.

Syalon 101 is the comprehensive option, with 0% porosity, thus ultra-low aluminium penetration, alongside high-strength properties and exceptional levels of toughness. This exceptional refractory ceramic can be used to produce hard-wearing riser tubes and heater tubes, outstanding thermocouple protection sheaths, and extrusion die equipment.

Refer to Silicon Nitride & Sialons Page for Further Details

If you would like any more information about the use of sialon in the aluminium industry, or about our advanced ceramics, please contact us.