SiAlON ceramics are innovative refractory materials based on the chemical composition of silicon nitride (Si3N4). They can compete with the strongest and most durable refractory materials currently available, due to their unique mechanical and thermal properties, with wide-reaching applications in metallurgical, petrochemical, and other high-temperature industries.

SiAlONs were designed to have crystal lattice structures which are isostructural with silicon oxynitride, but with broader cell dimensions, to allow for a denser refractory ceramic product. They are compounded from atoms of silicon (Si), aluminum (Al), oxygen (O), and nitrogen (N), which display short, high-strength intra-structural covalent bonds after sintering, creating a rigid atomic structure with high strength and high thermal efficiency.

International Syalons manufactures a range of SiAlON ceramics which utilize both beta (β) and alpha (α) SiAlON crystalline phases. Each of these phases has different physical properties and production requirements, with varying industrial applications. This article will explore these ceramics in more detail:

β-SiAlON

β-SiAlON uses the atomic formula Si6-zAlzOzN8-z in which z is equal to 0 – 4.2. The raw materials are combined with sintering additives such as magnesia (MgO) or yttria (Y2O3) so that the solution will adequately coalesce during the sintering process. SiAlONs are sintered using a process known as liquid phase sintering, which takes places at temperatures above 1700°C.

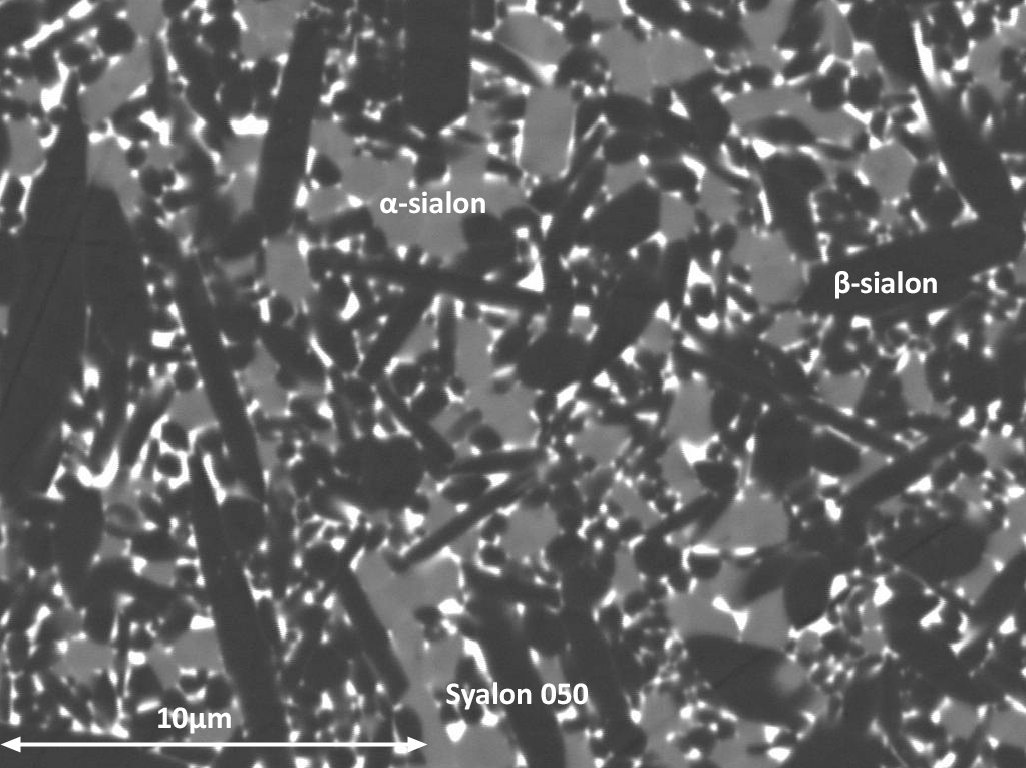

Densification of SiAlONs during liquid phase sintering happens more readily and at lower temperatures than that of silicon nitride, resulting in the reprecipitation of β-phase grains to form a dense crystalline structure of interlocked grains within a robust intergranular glass matrix with refractory-level thermal properties. These interlocking needle-like grains are what give β-SiAlON its high strength and toughness.

β-SiAlON ceramics are the foundation of many International Syalons materials; particularly Syalon 101, which exhibits a porosity of 0% and maximum temperature usages exceeding 1000°C.

α-SiAlON

α-SiAlONs are characterized not by interlocking needle-like grains, but by a fine equiaxed grain structure. This is achieved by a gradual reduction of the exuded liquid matrix, an increase in a cation such as yttrium and a very precise sintering process. The reduced amount of intergranular refractory glass and equiaxed grain structure results in a fully dense ceramic with increased wear resistance and high temperature capabilities.

In general, α-SiAlON is harder than β-SiAlON, but exhibit lower strength and toughness qualities. With this in mind, International Syalons’ 050 material is an α/β-SiAlON composite which contains both grain structures and in turn displays the best properties of both, including a hardness rating of 94 (HRA) – the highest hardness rating of our Syalon family of materials.

SiAlONs from International Syalons

International Syalons are experts in the fields of advanced ceramics, with 40 years’ experience developing advanced engineering materials for use in extreme refractory environments, from molten metal handling to petrochemical refineries.

We offer a robust range of SiAlON ceramics with outstanding thermal properties and service longevity, from ceramic thermocouple protection sheaths suitable for temperatures up to 1400°C, to immersion heater tubes for processing molten aluminium.

If you have any questions about our materials or products, please do not hesitate to contact us. Alternatively, browse our various resources for a deeper understanding of our product applications and specification.