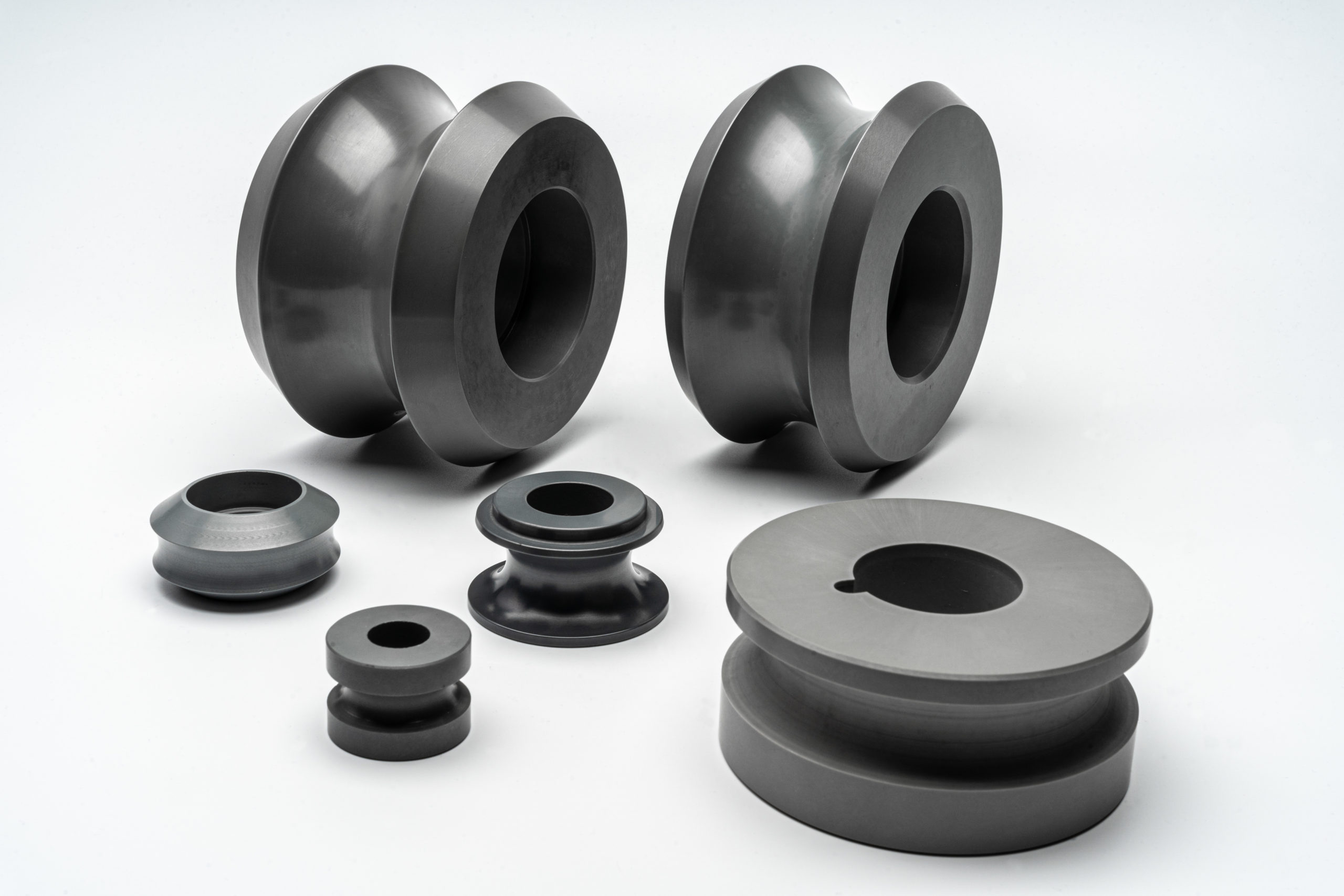

CERAMIC WELD ROLLS

International Syalons manufacture a range of silicon nitride and sialon advanced ceramic welding rolls for use in electric resistance welding (ERW). ERW is used to fabricate steel pipes and tubes, for example, by creating a forged weld.

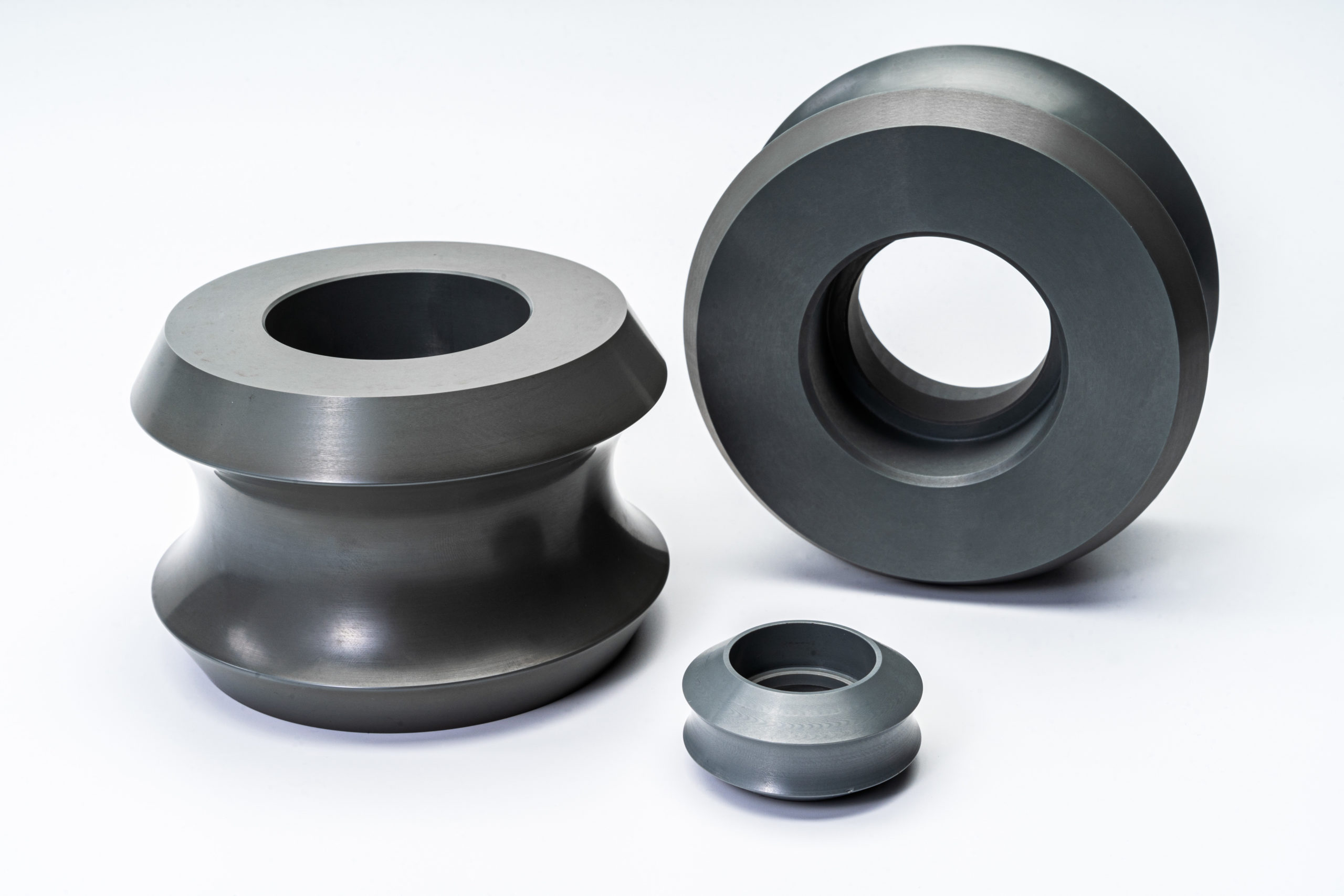

In the ERW process, the welding rolls (sometimes also known as squeeze rolls) apply the pressure to the tube while the metal is being heated, often by high-frequency induction heating, and this combination gives a forged weld.

This process puts a number of demands on the welding roll material. It requires high strength, thermal shock resistance, wear resistance and high electrical resistance. Also, the pipe temperature can approach the melting point of the metal and so high temperature stability is required.

International Syalons precision weld rolls eliminate material pick-up problems that are commonplace with high frequency welded tubes. This is particularly prevalent with non-ferrous materials where surface condition is critical. Stainless steel, brass and aluminium tube manufacturers can achieve substantially improved surface finishes with no risks of rolling weld spatter or particles into the tube surface. Some producers have even changed to ceramic rolls through the complete forming section of the mill.

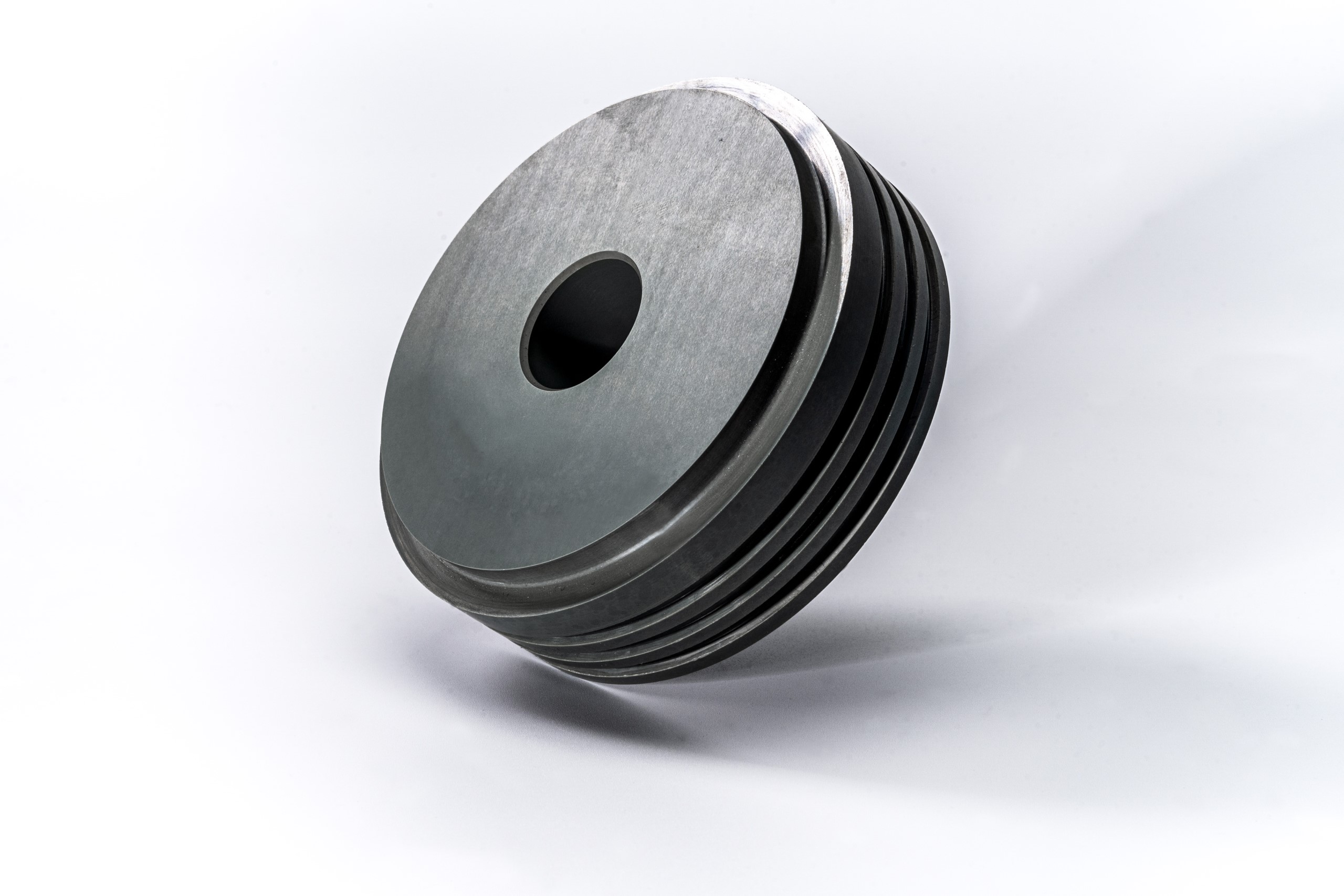

Sialons are silicon nitride based advanced ceramics characterised by excellent mechanical properties along with chemical and thermal stability, making them ideal for this application. Syalon 101 meets all the above mentioned requirements resulting in a number of key advantages over conventional metal weld rolls, such as improved pipe quality, reduced roll maintenance, reduced welding failures and reduced cooling requirement as the sialon rolls can operate at high temperatures. Syalon 101 weld rolls typically achieve up to 12 times more life than tool steel rolls.

Practical tests have shown that ceramic weld rolls can reduce HF weld power by as much as 30%. This actually also reduces unwanted ‘field’ heating of local components such as shafts, stands, lubrication points etc. Ceramic rolls also offer huge benefits for small diameter tubing manufacturers where upgrading to ceramic weld rolls can reduce weld vee length. This ensures more efficient positioning of the induction coil and impeder, which can reduce the H.A.Z. (heat affected zone) and produce a more aesthetically pleasing product.

For nearly 40 years International Syalons has been developing high quality engineering and process solutions for industry. Our current range for the tube industry includes weld and forming rolls, seam guides, tube expanders and calibration drawing dies.

The successful integration of advanced technical ceramics into engineering systems requires close collaboration between you, the end-user, and ourselves, the material manufacturer. Please call +44(0)191 2951010 or email for an initial consultation with our technical sales team, or send us a Request for Quote.

Download our Ceramic Weld Rolls brochure or Metal Forming Applications guide for more details.

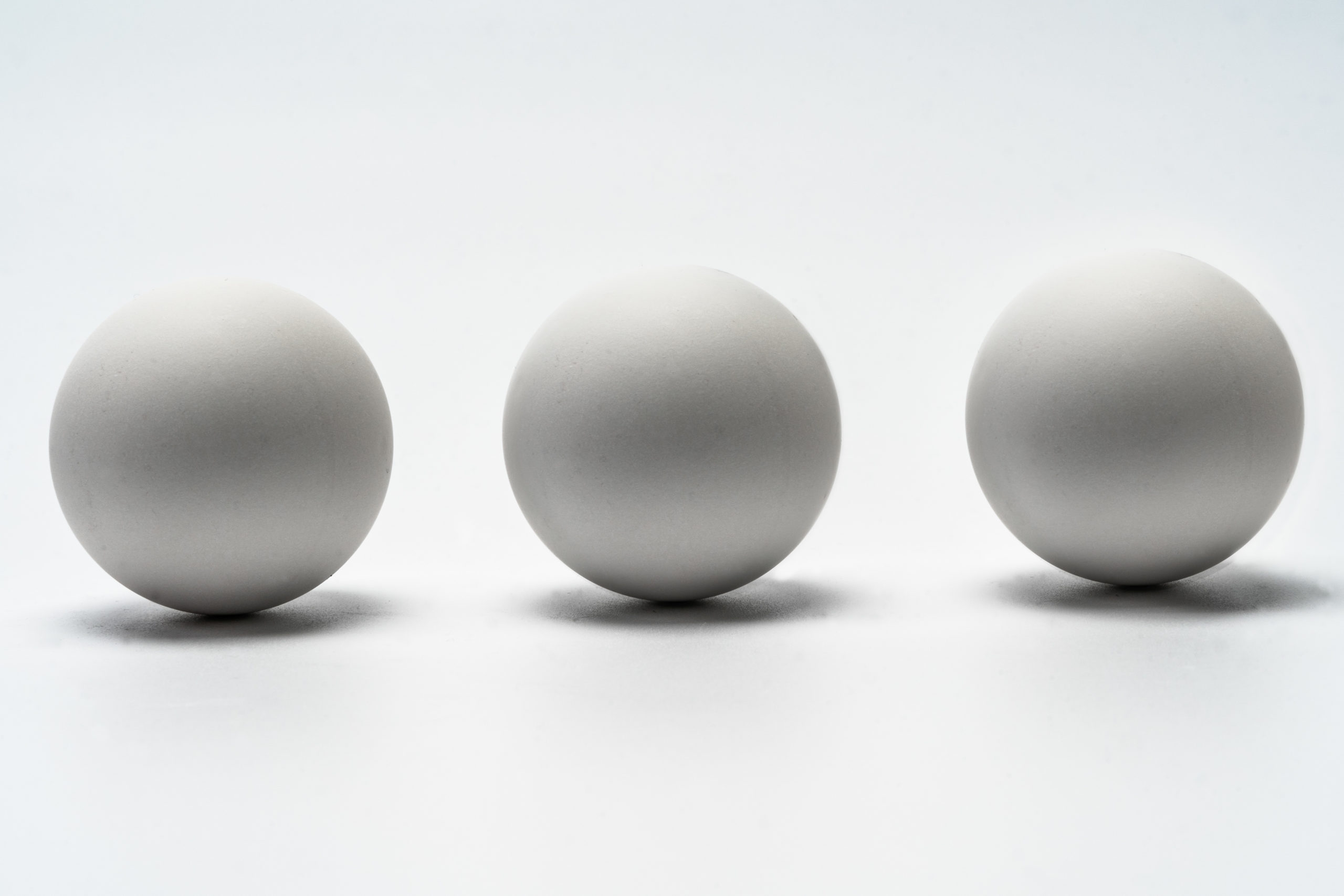

Syalon 101 is a grade of sialon which offers the best general combination of properties. These include high strength, hardness and toughness as well as excellent corrosion resistance.

Syalon 050 is suited to wear and high temperature applications. It has extreme hardness combined with high strength and can be used in applications up to 1400°C in air.

Syalon 110 is silicon nitride-boron nitride composite, offering high temperature corrosion resistance in challenging molten metal handling applications.