CERAMIC CRUCIBLES AND LADLES

Metal casting places enormous demands on foundry handling equipment – especially melting crucibles and pour/transport ladles. The aggressive chemistries and intense temperatures of molten metals can have a range of synergetic effects that erode the efficiency and longevity of critical components. Downtime associated with wear and tear can be extremely costly. So, it is important to select the right materials that promote long-term efficiency gains through increased throughput, uptime, and critical resistivity. Technical ceramics are the perfect solution.

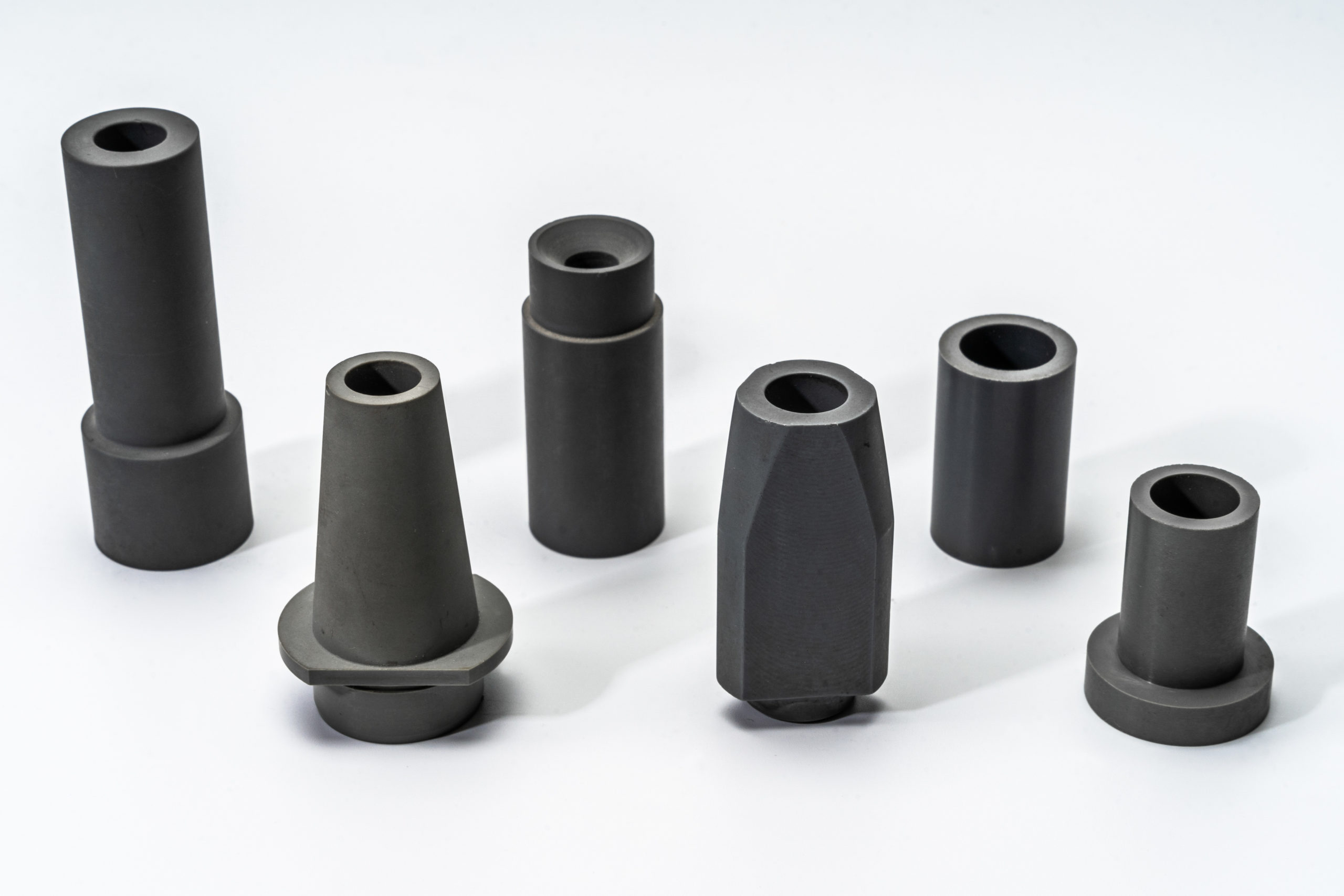

Syalon 101 ladles and crucibles are premium foundry handling solutions designed for high-efficiency management of non-ferrous metals – including aluminium and its alloys, and zinc. Our technical ceramics enable engineers to benefit from the superior thermomechanical properties and corrosion resistance of silicon nitride at a more reasonable investment price. This is due to the unique properties of sialon alloys which are easier to bind, form, and machine than conventional Si3N4 without compromising on performance.

Syalon 101 provides exceptional chemical and thermal stability, outperforming traditional materials like cast iron and other ceramics (alumina, silicon carbide, etc.), ensuring outstanding service life with limited contamination. Perfect for pouring and transporting, Syalon 101 ladles designed to handle molten aluminium can be engineered to suit a range of processing lines – including highly automated systems. They are reliable, cost-effective, and can help to add functionality to your casting plant during the digital transformation.

For applications where temperatures may exceed 1200°C, we recommend Syalon 050. This material maintains excellent physical properties even at temperatures reaching 1400°C. Our foundry crucibles and ceramic ladles even champion energy-efficiency by requiring no preheating for even intensive use cycles. Although sialon ceramics exhibit minimal wetting intrinsically, some applications may require extremely low tolerances to melt adherence. In those instances, ladles can be coated with a non-wetting boron nitride coating.

The ceramic ladles and crucibles manufactured by International Syalons are very easy to use. For example, there is no need for preheating. Also, Syalon possesses minimal wetting, so adherence of the melt is kept to a minimum, although this behaviour depends on the melt temperature and the alloy composition. For those situations which require it, we can coat the ladles with a non–wetting boron nitride coating.

The successful integration of advanced technical ceramics into engineering systems necessitates close collaboration between you, the end user, and us, the material manufacturer. For an initial consultation with our technical sales team, please call +44(0)191 2951010 or email . For advice on using our foundry handling equipment, including foundry ladles and foundry crucibles, in molten metal handling applications, please download our User Guide.

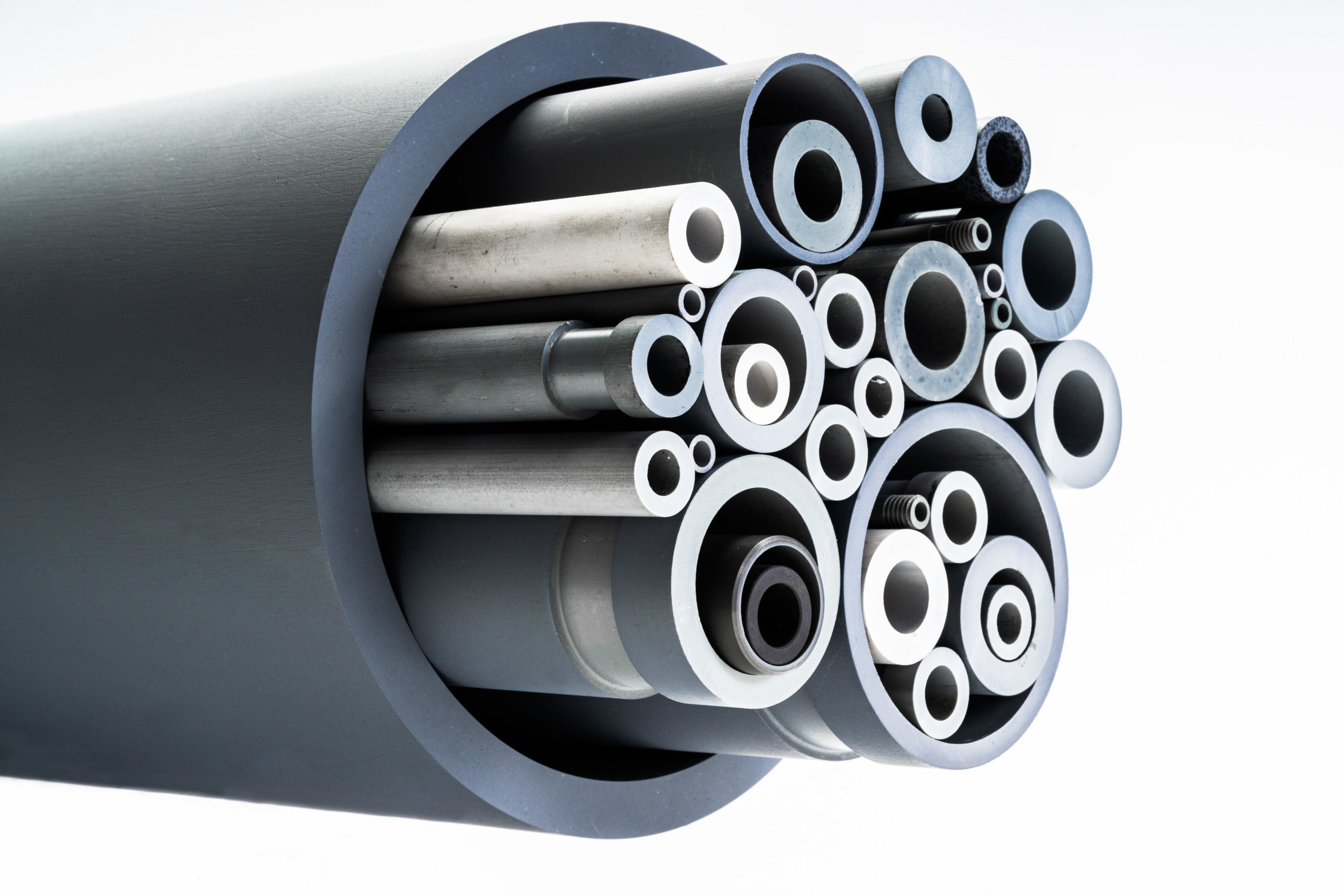

International Syalons manufacture a range of silicon nitride and sialon advanced ceramic thermocouple protection sheaths for use in the aluminium and molten metal handling industries.

Syalon is the preferred choice when looking to improve nozzle wear resistance, outperforming many competitive materials such as alumina and tungsten carbide.

International Syalons manufacture a range of standard and bespoke silicon nitride and zirconia ceramic weld location and control pins, which are used for precise captive nut welding.