YOUR CHALLENGES

Tackling industrial manufacturing's biggest challenges requires an innovative mindset and a holistic approach to problem-solving. With over 50 years' experience in pioneering R&D, we combine technical materials expertise with solution-oriented customer service to supply advanced ceramics designed to overcome your challenges. Browse common manufacturing and production pain points below to see how we could help you realise true production gains, cost savings, and greater supply chain resilience.

Abrasive Wear

Abrasive wear is one of the most prevalent failure modes in industrial equipment. Whether you’re experiencing premature failure in nozzles, erosion in grinding systems, or contamination in sensitive processes, we can provide a tailored ceramic solution.

CHEMICAL RESISTANCE

Industrial equipment operating in chemically aggressive environments must endure far more than wear. Whether you're operating a molten metal transfer system, a chemical reactor, or a slurry pump, our team can help implement high-performance ceramics to reduce failure rates and extend service life.

CONTAMINATION

Contamination challenges are routine applications requiring high purity, including sample preparation, molten metal processing, and fine-powder milling. We can help you minimize contamination at the material level, whether you're managing high-purity material streams, casting reactive alloys, or preparing analytical samples,

Corrosion

The causes of corrosion in industry are varied, multifaceted, and difficult to combat. We offer corrosion-resistant ceramic alloys designed to withstand the most aggressive industrial environments.

CRACKING

Cracking in industrial components is a frequent and costly mode of failure, particularly in systems exposed to rapid temperature fluctuations, repeated mechanical impacts, or long-term thermal loading.

CREEP

Mechanical creep—the slow, progressive deformation of materials under mechanical stress at elevated temperatures—is a major reliability issue in high-temperature operations.

Erosion

Erosion in materials is a persistent and costly issue across industrial processes involving abrasive particles, pressurized fluids, and extreme temperatures. International Syalons offers a suite of sialon ceramics engineered for extreme erosion resistance.

Fatigue

Fatigue failure of materials is a critical concern in industrial components subjected to cyclic mechanical or thermal stress. International Syalons offers a suite of sialon ceramics engineered to resist fatigue through superior mechanical resilience, thermal stability, and oxidation resistance.

Maintenance Costs

Maintenance costs in industrial operations are driven by frequent component failures, high labor inputs, and unexpected equipment downtime. International Syalons delivers engineered sialon ceramics that extend component life, reduce failure rates, and improve equipment reliability in harsh operating environments.

Metal adhesion

Metal adhesion is a major challenge in industries like foundry operations, extrusion, wire drawing, and welding. International Syalons offers engineered ceramics with non-wetting surfaces, high thermal stability, and chemical inertness, helping to eliminate adhesion in molten metal applications.

Oxidation

Oxidation is a major cause of component failure in high-temperature industrial systems. International Syalons offers engineered ceramic materials that withstand oxidation at extreme temperatures through dense microstructures, non-wetting surfaces, and stable oxide layer formation.

Quality issues

Preventing quality issues in high-performance industries limits the risk of operational failures, process inefficiencies, and elevated costs. International Syalons delivers materials and manufacturing processes built around dimensional control, microstructural stability, and compliance with international quality standards.

Supply Chain Issues

Global industry always faces supply chain issues related to material shortages, trade friction, and ever-rising energy costs. International Syalons provides end-to-end ceramic manufacturing in the UK.

Thermal Shock

Thermal shock occurs when components experience rapid temperature shifts that create internal stress — often leading to cracking, delamination, or sudden failure. International Syalons develops advanced ceramics engineered for stability under extreme temperature changes.

Weight Savings

Weight is a critical factor in industrial operations — affecting energy use, handling ease, system wear, and component lifespan. International Syalons develops sialon ceramics that combine low density with exceptional durability, offering the strength of advanced ceramics at a fraction of the weight of metals or traditional alternatives.

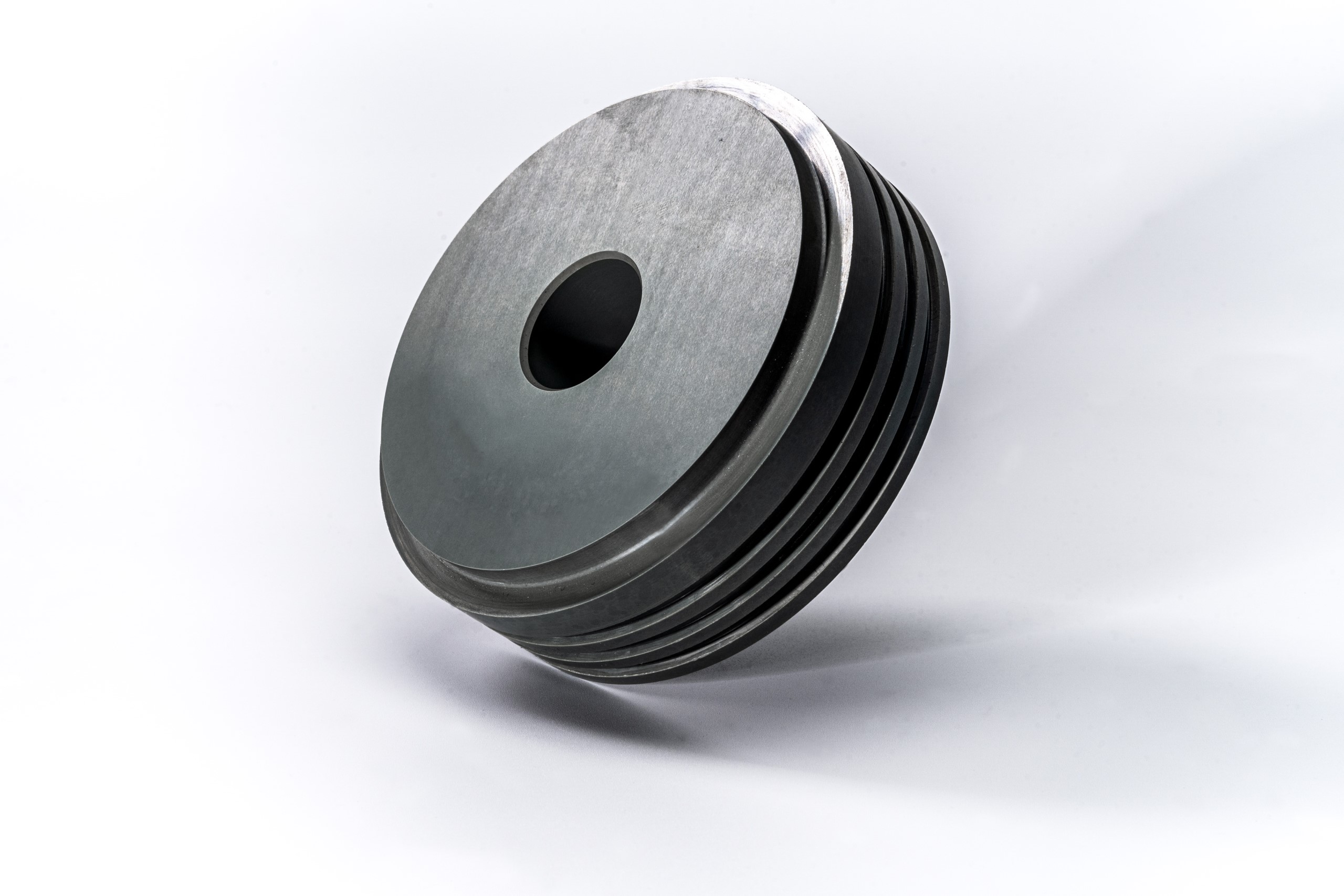

Providing unmatched performance properties under extreme levels of stress, advanced ceramics help designers and engineers to push production boundaries and deliver innovative solutions to the many industrial challenges we face today. Advanced ceramic materials promote greater efficiency throughout manufacturing and production chains, by withstanding severe stress with little-to-no loss of function over time. Technical ceramics represent some of the hardest wearing engineered materials on earth, which translates to unprecedented erosion resistance and industrial wear performance.

The advanced ceramics available from International Syalons are extremely stable and fully dense, which imparts outstanding resistance to corrosion in chemical and process industries. Virtually all advanced ceramic materials also exhibit superb thermal properties, enabling their application in a comprehensive range of extreme temperature environments.

Advanced ceramics are on the forefront of technical achievement in engineering and industrial processing, from clean energy development to ultrafast telecommunications. Please call +44(0)191 2951010 or email for an initial consultation with our technical sales team or send us a Request for Quote.

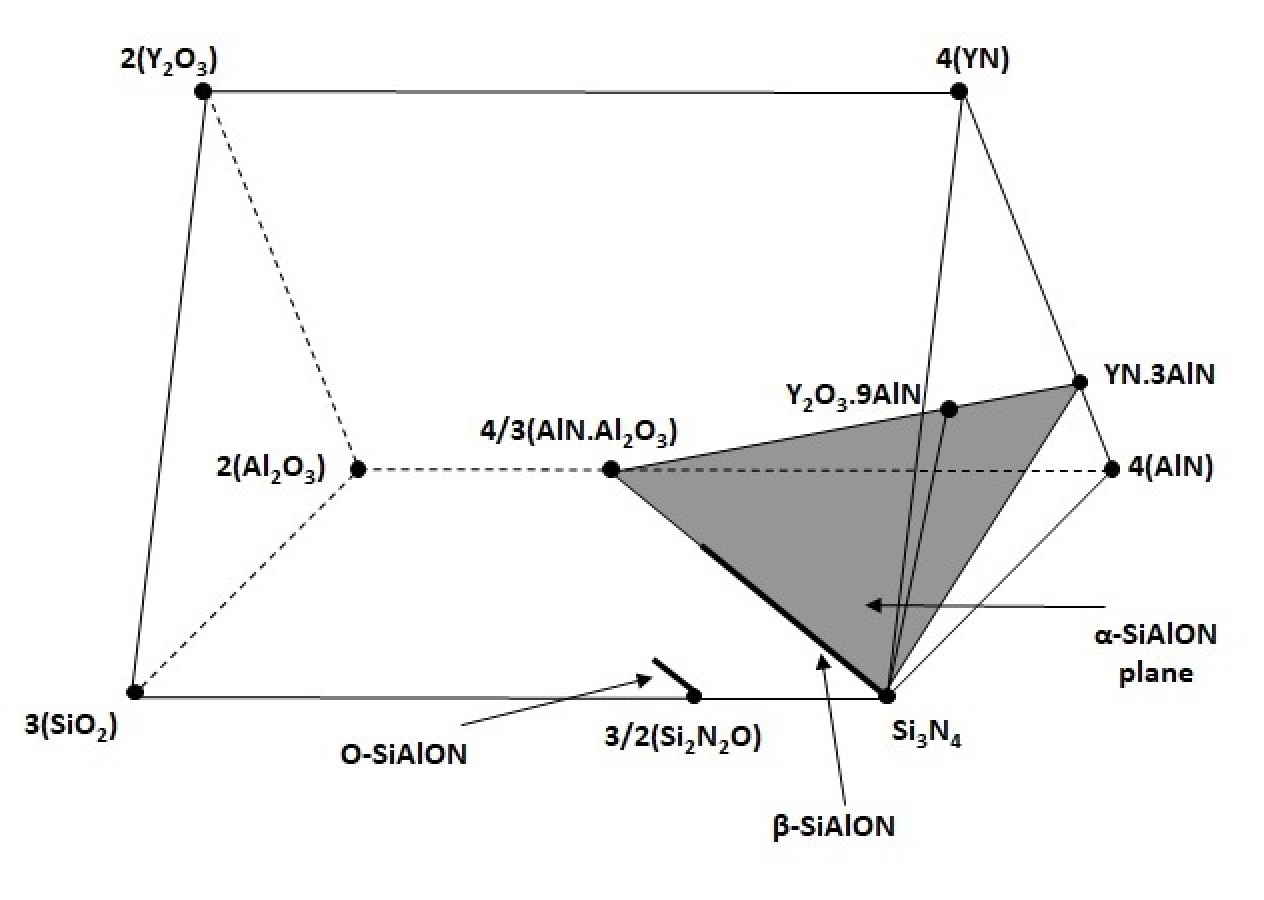

What are sialon ceramics?

Technical ceramic property comparison table

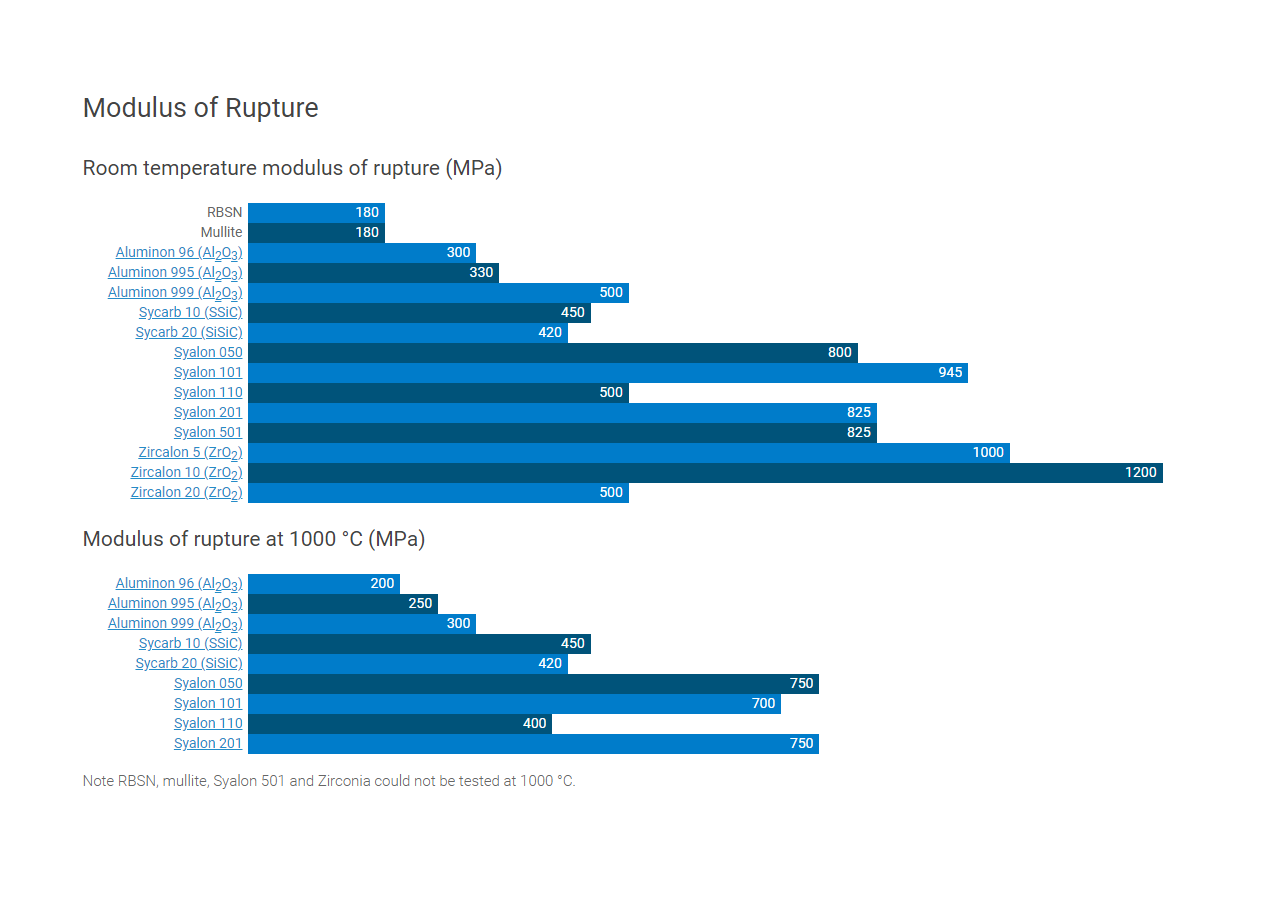

Syalon 101 is a grade of sialon which offers the best general combination of properties. These include high strength, hardness and toughness as well as excellent corrosion resistance.

Syalon 050 is suited to wear and high temperature applications. It has extreme hardness combined with high strength and can be used in applications up to 1400°C in air.

Zircalon 30 is a co-stabilised zirconia-based ceramic with an alumina matrix, which is reinforced by self-grown alumina-based platelets and offers outstanding fracture toughness.