ww.syalons.com/materials/silicon-nitride-sialon/Technical ceramics like sialons and zirconia are among the most advanced materials ever engineered by mankind, enabling new application areas that were practically impossible before their commercial realisation. With many technical ceramics, there is a substantial overlap between their thermomechanical and chemical properties, which can complicate ideal material selection for distinct applications. In the case of sialons and zirconia however, the materials can be easily and respectively distinguished as a non-oxide and an oxide ceramic.

In this blog post, International Syalons aims to explore how that fundamental difference underlines a raft of contrasting qualities and properties between sialons and zirconia.

An Overview of Sialons

Non-oxide technical ceramics are a key innovation in materials engineering, representing a wide group of ceramics that do not primarily consist of metal oxide compounds like alumina (Al2O3). Sialons emerged as a critical example of the outstanding properties of non-oxide technical ceramics in the 1970s, exceeding conventional silicon nitride (Si3N4) in terms of ease-of-fabrication and manufacturing costs.

For more information, read our Introduction to Sialons Ceramics

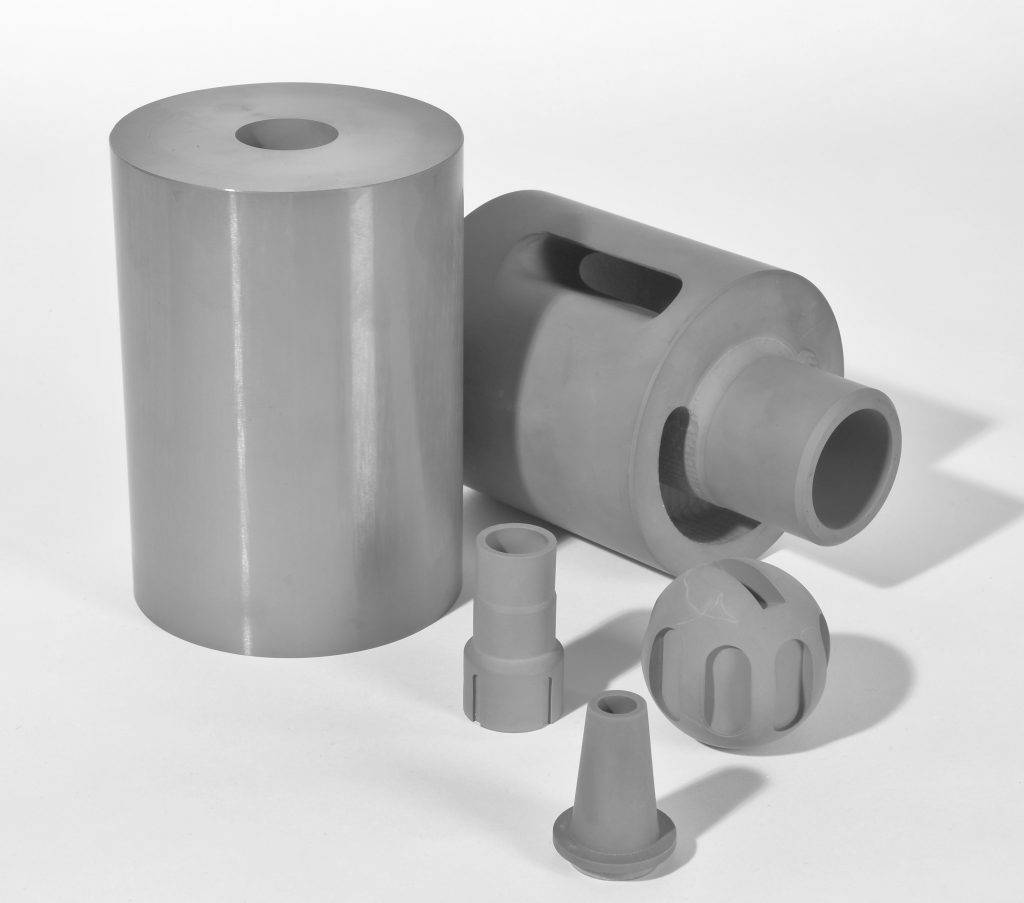

Sialons are semi-crystalline technical ceramics that exist most commonly as either a beta (β) or alpha (α) crystalline phases with a crystal lattice that is isostructural with the corresponding phase of silicon nitride. Comprising high-strength covalent bonds of silicon (Si), aluminium (Al), oxygen (O), and nitrogen (N), the unique combination these elements in the presence of well-established sintering additives and ceramics expertise is useful for engineers in a range of downstream application areas. International Syalons offers four proprietary grades of sialon technical ceramics:

- Syalon 101: Our foundational grade, Syalon 101 is a β-sialon ceramic that offers an outstanding balance between high hardness, toughness, and strength.

- Syalon 050: Optimised for higher wear-resistant characteristics, Syalon 050 is a mixed α: β-sialon with exceptional high temperature thermomechanical characteristics.

- Syalon 110: A unique composite of β-sialon with boron nitride (BN), Syalon 110 was engineered for improved anti-corrosive properties and exceptional thermal shock characteristics.

- Syalon 501: Another innovation on the fundamental successes of sialons, Syalon 501 is a tailor-made technical ceramic that was engineered to exhibit an electrical conductivity sufficient for EDM machining.

An Overview of Zirconia

Despite the significant progress of non-oxide ceramics, oxide ceramics still occupy important segments of manufacturing and engineering spaces. Zirconia, or zirconium dioxide (ZrO2), is one of the most enduring technical oxide-based ceramics with exceptional high-temperature characteristics and unmatched fracture toughness properties.

For more information, read our Introduction to Zirconia

Like sialons, zirconia is available in three distinct crystallographic phases and must be stabilised with additives such as yttria, magnesia and/or ceria to eliminate the risk of the material undergoing phase transitions at typical operating temperatures. International Syalons offers four grades of stabilised zirconia:

- Zircalon 5: An “entry-level” grade of zirconia offering typical high temperature strength and wear resistance.

- Zircalon 10: A fully-dense yttria-stabilised-zirconia technical ceramic with a modulus of rupture (MoR) of 1200 megapascals (MPa), Zircalon 10 can resist continuous wearing and large impacting forces.

- Zircalon 20: A proprietary grade of magnesia-stabilised zirconia (MSZ), Zircalon 20 has improved thermal shock resistance for higher-temperature applications.

- Zircalon 30: A market leading high temperature resistance zircona which offers an unparalleled fracture toughness of 14-15 MPam1/2, without any detriment to strength or hardness.

Which is Most Effective: Sialon or Zirconia?

It is impossible to prescribe a single material for all industrial applications, but sialons typically offer broader heat- and wear-resistant characteristics to suit a wider range of application areas. However, for industries where abrasion or impact is a higher concern than temperature, zirconia may provide improved performance. Refer to our introductory articles on each of these materials for more details. Otherwise, contact International Syalons today with any questions about our technical ceramics.