Updated 25/05/2022:

Digitalization and enhanced automation in industrial settings are now ushering in a fourth industrial revolution (Industry 4.0), which is fundamentally fuelled by advances in materials like technical ceramics.

What is Industry 4.0?

Humanity’s technical achievements have been founded on the ability to reinvent and revolutionise existing innovations. At one point in history, the use of draft animals was the height of labour efficiency. This was surpassed by the genesis of steam power which liberated manufacturers and ushered in a new age of mechanization. Gas, oil, and electricity eventually surpassed steam, and nuclear power ultimately overtook those. Each of these innovations was so profound that they have come to define three distinct eras based on their industrial capacities; also known as the first three industrial revolutions.

Industry 4.0 is a term used to describe a new era of interconnectivity between devices and systems in factory settings, contributing to the actualization of so-called smart factories capable of autonomously visualising and monitoring production chains to make informed manufacturing decisions. Although some engineers deny that the impact of digitalization will be quite so profound, it looks increasingly likely that exponential growth in factory automation and smart computing will lead down this particular road. Consequently, technical ceramics are uniquely poised to affect and be affected by this rapid rate of change.

Some aspects of industry 4.0 that are particularly prevalent for technical ceramics include:

- Additive manufacturing (AM): Also known as 3D printing, AM technical ceramics are a significant breakthrough for rapid prototyping and bespoke engineering of intricate components with outstanding thermodynamic properties. Generating individual components via CNC deposition is much more energy efficient and sustainable than bulk sintering for research and development (R&D) or proof-of-concepts. These components can, in turn, facilitate enhanced functionalities for a broad range of end-use mechanisms.

- Internet of Things (IoT): Central to improving the interconnectivity of both devices and systems is the generation of a robust communication network, often referred to as IoT. Technical ceramics form the basis of these architectures, providing the framework for high-density electronic elements with extremely small form factors. This is critical for establishing a reliable, long-serving system of communication that adds value to existing production chains.

Technical Ceramics from International Syalons

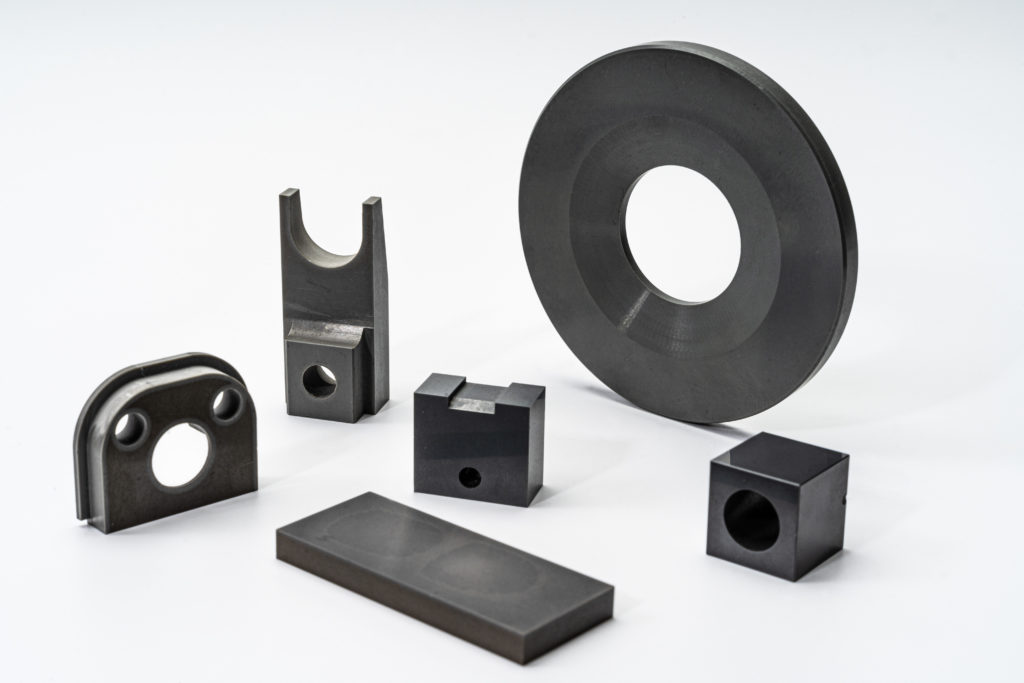

International Syalons is a global supplier of technical ceramics, providing the materials for tomorrow’s industry challenges today. Industry 4.0 is already impacting many workshops and factories the world over. The extent to which this is changing the face of production lines and supply chains depends on the rate of uptake with respect to key technological breakthroughs, from AM and IoT to robotics and artificial intelligence (AI).

We offer a broad range of technical ceramics that can rise to the challenges of a new industrial age. If you would like more information about how International Syalons is championing innovation in technical ceramics, simply contact a member of the team today.