Corrosion-resistant ceramics are often mandatory in harsh environments, namely in the oil and gas industries. This is because ceramics provide high levels of corrosion and thermal resistance and have outstanding wear, and these fundamental properties make them more suitable than traditional metal components.

This article will look at several case studies on corrosion-resistant ceramics and what makes them such essential materials.

Case Study 1: Compatibility of Molten Metals with Syalon Ceramics

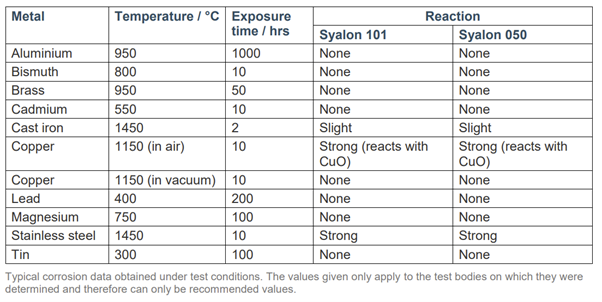

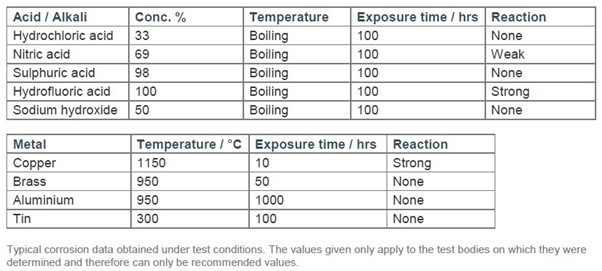

Advanced Syalon ceramics have been proven to hold very high resistance to corrosion by molten metals. The following case study has shown the compatibility of Syalon 101 and Syalon 050 when in contact with molten metals. Please note, the reactions depend highly on the application and the environment, and the given data should be used as a guideline.

Case Study 2: Syalon 101

Syalon 101 is used in many applications that require high strength, thermal shock resistance, toughness and high wear resistance. It is the first of the Si-AlO-N family of ceramic materials that we have carefully developed and designed especially for high-strength applications, but those which do not continuously exceed 1000oC.

Here is a summary of the key findings of this case study:

Corrosion Resistant Ceramics with International Syalons

We design and manufacture a wide range of ceramic products used in an ever-growing range of applications. Our products are made of alumina, sialon and zirconia and include balls, foundry products, seals, tubes and more. These products are utilised for their corrosion, thermal resistance, and excellent wear properties.

Corroded temperature sensor and heating element. Image Credit: Shutterstock.

Foundry Handling Equipment

We produce numerous products that handle non-ferrous metals and chemicals in the chemical and process industries. Typical pieces of equipment include crucibles and ladles, which we manufacture with silicon nitride, Syalon 101 and occasionally Syalon 050. These materials offer outstanding chemical and thermal stability and corrosion resistance and are non-wetting. All these properties contribute to our products’ cost-effectiveness, longevity and process reliability.

There are more case studies pending, with various molten metal handling components currently in trial. One example is a series of exhaust gas flue detector plates designed to protect metal components from molten aluminum slag in recycling furnaces. Thus far, they have shown no signs of attack after a three-month period.

Thermocouple Protection Tubes

Our thermocouple protection tubes are manufactured in the aluminium and molten metal handling industries using silicon nitride and sialon. These advanced ceramic tubes provide many crucial properties, such as high strength, thermal stability, and outstanding corrosion and thermal shock resistance. They are manufactured with Syalon 101 and 050, as mentioned above.

We have generated Syalon 101 protection tubes for biological waste incinerators, where processing conditions are both challenging and variable. Waste is a heterogeneous mix of different substances, meaning there is no way to maintain uniformity during incineration–temperatures can randomly spike up to 1100C. Additionally, biological waste incineration is associated with extremely complex chemistries. Not only are fumes immensely toxic, but corrosive solutions are routinely created when ash is mixed with water during wash down procedures. Compounding all that, waste is dropped into furnaces from above, which can cause impact damage to burner tubes. Generally, burners will last around four months. Syalon 101 tubes are currently going strong after a nine month period.

Silicon nitride thermocouple protection tubes. Image Credit: International Syalons (Newcastle) Ltd.

Heat Exchanger Tubes

We have developed heat exchanger tubes for extremely harsh environments, such as hydrogen bromide (HBr), bromine (Br2), and hydrochloric acids (HCl). Sialons are the only materials that can withstand attack from such substances at temperatures approaching 150C.

Please visit our product page or blog for more information about ceramic products in our oil and gas industry. Alternatively, if you’re ready to make a purchase, get in touch with us today and let’s provide you with the most suitable product for your application.