Ceramics have been exploited by mankind for over 26,000 years. They have been so central to human engineering that it is impossible to pinpoint a singular origin of the pottery-making process. Archaeologists have coined the term “linear pottery culture” to define the period when ceramics were simultaneously and independently discovered by different peoples across Neolithic Europe. Yet the significance of technical ceramics spans far beyond archaeological curiosity, pervading several key periods of history and every phase of industrial progress into the modern age and the future.

Continue readingDesign Tips for Silicon Nitride Ceramics

Silicon nitride ceramics (Si3N4) occupy a storied niche in the history of engineering materials, rising from relative obscurity in the early days of the industrial era to become one of the most important technical-grade ceramics available today. Since their renaissance in the early 1970s, silicon nitride ceramics have successfully replaced numerous legacy materials as the advanced ceramic of choice for various high-performance components. These include:

Continue readingSialon Vs Silicon Carbide

In the field of material technology, nonoxide technical ceramics are among the most recent developments. They are increasingly being used for a range of applications thanks to their chemical, thermal, and mechanical properties. Both sialon and silicon carbide (SiC) ceramics are useful candidates for energy conversion and production. Already, they have shown exceptional prowess in abrasive environmental applications and those which involve harsh chemicals. So, what are the differences between sialon and silicon carbide, and which applications does each best serve? Here, International Syalons takes a closer look.Continue reading

Comparing the Fracture Toughness of Zirconia Ceramics

Zirconia ceramics represent the primary application for the compound zirconium dioxide (ZrO2), accounting for over half of the world’s zirconium demand. Recent reports suggest that the global zirconia market will top 1.5 million tonnes by 2022; meaning global demand of the raw mineral purely for zirconia ceramics manufacturing could top 750,000 tonnes in a few short years. Estimates suggest that this is less than 1% of the world’s total zirconium reserves.Continue reading

Insight into the Hardness of Zirconia Ceramics

Zirconium dioxide (ZrO2) is one of the most well-characterised ceramic materials on earth. It occurs naturally in the mineral baddeleyite, which primarily adopts a monoclinic crystalline structure: one of the three primary forms of the material. The most widely-known form of zirconia is the cubic crystal phase which often serves as a cost-effective diamond substitute. However, estimates suggest that demand for zirconia ceramics accounts for as much as 54% of the worldwide zirconium market[1].

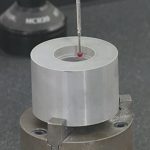

Ceramics Engineering: Pressure Vs. Pressureless Sintering

Sintering is arguably the most important step in the ceramics manufacturing process. It is the phase when the green-body is fired at temperatures approaching the ceramic powder’s melting point, causing the consolidated raw material to undergo numerous chemical and physical changes. Several distinct sintering methods exist, but each one essentially exploits the same properties of ceramics to form a densified workpiece with desired properties and material characteristics.Continue reading

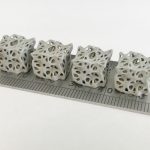

Supplementing Advanced Ceramics Manufacturing with 3D Printing

Lithographic additive manufacturing of advanced ceramics is an emergent technology that is unlikely to replace conventional bulk sintering and machining any time soon – if ever. This is due, primarily, to the scale and precision of components manufactured via 3D printing.

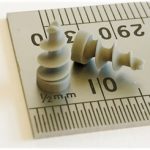

Continue readingCreating High Temperature Microturbines with 3D Printing

Armed with innovative 3D printing technologies, engineers have designed a new generation of microturbines capable of unparalleled operating efficiency at higher speeds and elevated temperatures.

Continue reading3 Key Benefits of 3D Printed Ceramic Materials

As part of the European Commission funded Horizon 2020 project ToMax, International Syalons in collaboration with European partners has demonstrated the unique capabilities of lithographic-additive manufacturing (L-AMT) of ceramic materials including Syalon 101.

Continue readingA Quick Intro to Additive Manufacturing Ceramic Solutions

Additive manufacturing (AM) of ceramics, also known as ceramic 3D printing, is an attractive engineering solution for challenging applications. Technical ceramics, like silicon nitride (Si3N4), largely outperform industrial-grade polymers and metals for high-temperature operations, with superior mechanical properties and thermodynamic stability. Yet these same properties make ceramics difficult to use as a feedstock in additive manufacturing processes.

Continue reading