International Syalons are now halfway through the 3 year ToMax project and are working closely alongside consortium partners Lithoz to develop lithographic additive manufacturing technology (L-AMT) for silicon nitride materials.

The EU funded Horizon 2020 project has united industrial know-how from across Europe in the fields of software development, photopolymers and ceramics, high performance light-sources, system integration, life cycle analysis, industrial exploitation and rewarding end-user applications, with the end goal of producing 3D-printers with high throughput and outstanding materials and energy efficiency.

The ToMax consortium is taking innovative, resource-efficient manufacturing processes to develop energy-efficient L-AMT machinery, with a focus on manufacturing of alumina, silicon nitride and cermet parts with high shape complexity for aerospace and automotive engineering, medical devices, and energy efficient lighting applications.

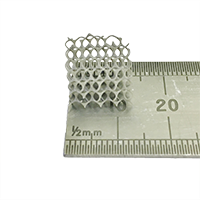

Results so far have been ground-breaking as the project has already produced fully dense, extremely complex Syalon 101 and 050 grade parts with excellent surface quality, and initial testing indicates the same mechanical properties as conventionally fabricated Syalon 101, as shown in the table below.

| Material | Density (g/cc) | Hardness (Hv10) | 3 point Modulus of Rupture (MPa) |

|---|---|---|---|

| 3D-printed Syalon 101 | 3.25 | 1500.5 | 951.3 |

| Iso-pressed Syalon 101 | 3.25 | 1500.0 | 945.0 |

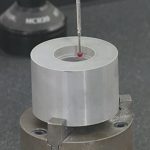

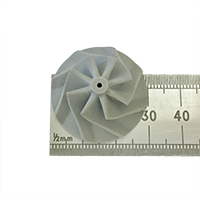

The video below demonstrates the excellent thermal shock resistance of a 3D-printed Syalon 050 impeller. The impeller is quenched from 800°C in to water at room temperature and survives intact.

The focus for the remainder of the project will be to perfect the manufacturing process, and work closely with end-users to develop complex new parts for applications where Syalon is the most suitable material and  L-AMT is the only method of fabrication.

L-AMT is the only method of fabrication.

International Syalons are extremely excited and encouraged by recent developments in the additive manufacturing of advanced ceramics, and are looking forward to adding this fabrication method to their already well established production capabilities. Enquiries regarding L-AMT Syalon are welcomed. Please contact us for further details.

Related Posts

-

Design Tips for Silicon Nitride Ceramics

Silicon nitride ceramics (Si3N4) occupy a storied niche in the history of engineering materials, rising…

-

Benefits of Silicon Nitride Milling Media

Advanced ceramic grinding media are on the cutting-edge of wearing applications. The right grinding balls…

-

Introducing Additive Manufacturing for Silicon Nitride Ceramics

Additive manufacturing (AM), also known as 3D-printing, is the process of designing and manufacturing intricate…