Additive manufacturing (AM), also known as 3D-printing, is the process of designing and manufacturing intricate geometries from a limitless range of materials using innovative deposition techniques. The equipment involved deposits small amounts of a given material into predetermined channels to form small, complex components – as opposed to conventional manufacturing processes which subtract from materials through milling and machining, or pressing and extrusion.

AM processes have been on the rise since the 1980s, with the invention of bioprinters and the wider commercial availability of generic 3D-printers, which have enabled the formation of increasingly intricate shapes from broadening ranges of materials. From an industrial perspective, it represented significant promise for the formation of complex refractory components using silicon nitride ceramics.

The Challenges of Complex Ceramic Shapes

Conventional methods for manufacturing complicated silicon nitride ceramic shapes such as spherical high-density green bodies have yielded difficult and costly results. This is primarily due to the expensive molds, extended formation periods, and poor sintering yields, which have reduced the commercial practicality of manufacturing elaborate refractory shapes.

Successful AM of Silicon Nitride Ceramics

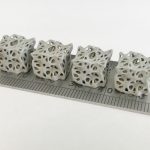

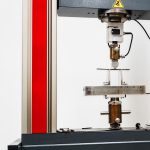

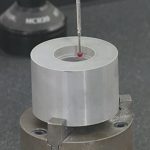

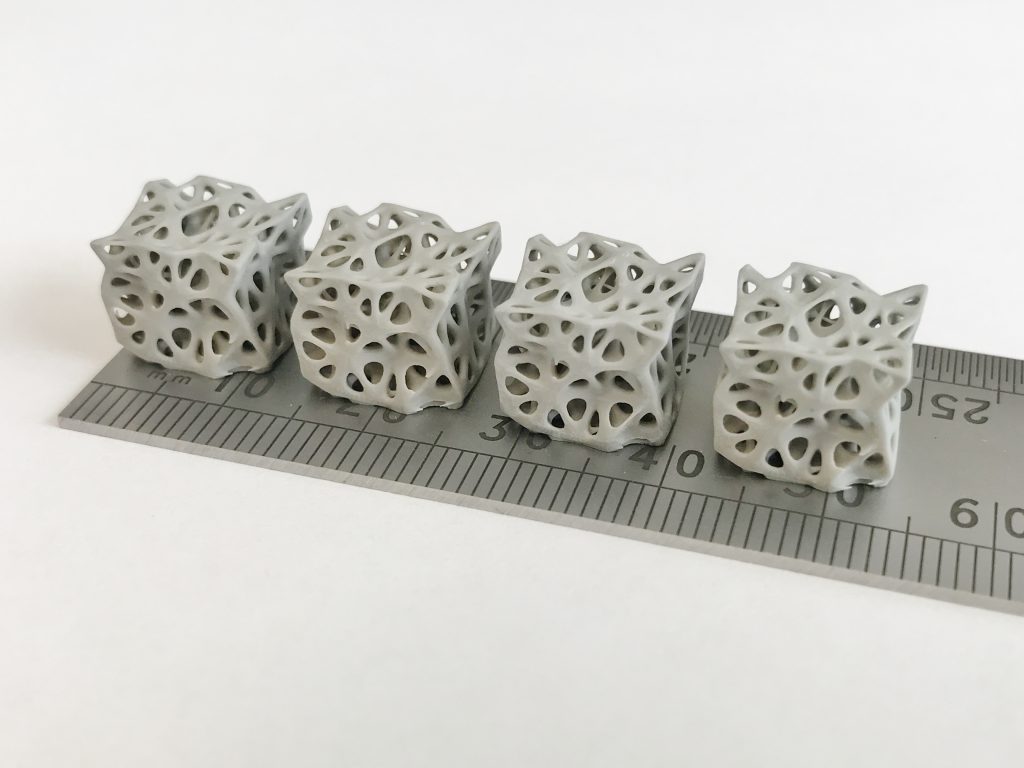

International Syalons has now successfully manufactured silicon nitride ceramics through AM processes, achieving near-identical thermal and high strength properties as materials produced through iso-static pressing.

| Material | Density (g/cc) | Hardness (HV10) | Ave Biaxial Stress (MPa) | Equivalent 3pt MOR (MPa) | Weibull Modulus |

| L-AMT Syalon 101 |

3.25 | 1500.5 | 763.8 | 951.29 | 6.7 |

| Iso-static pressed Syalon 101 | 3.25 | 1500.0 | 770.0 | 945.0 | 11 |

Yet this technology has not been developed to replace conventional manufacturing methods for silicon nitride ceramics.

AM of silicon nitride ceramics is capable of producing components of previously impossible shapes and sizes, with suitability for high-technology applications or prototype technologies. It is not expected to replace the established large-scale production of bigger components – nor was it designed to. It can support traditional manufacturing processes by enabling previously unforeseen designs.

3D-Printed Silicon Nitride Ceramics from International Syalons

International Syalons was the first company to patent and develop sialon ceramics for industrial markets, and we are committed to innovation in the advanced ceramic industry. We provide a range of advanced ceramic materials, including five distinct grades of silicon nitrides suitable to a range of different applications – and our AM silicon nitride ceramics perform to the same mechanical requirements as the traditionally manufactured variants. These technologies are now readily available for the formation of high precision AM silicon nitride ceramic components.

We will be exploring AM of silicon nitride ceramics in more detail in a forthcoming article, but if you would like any more information about our products, please contact us.