The demanding specifications of shot blasting equipment require high-performance materials capable of withstanding sustained pressures and temperatures. Conventional metals with outstanding hardness values are routinely used to prepare tough shot blast nozzle linings, but they are incapable of competing with the unique mechanical stability of advanced ceramics like silicon nitride.

This article will explore the capacities of advanced ceramic shot blast nozzles in more detail:

What is a Blast Nozzle?

Shot blast nozzles are the outlet component for industrial shot blasting surface preparation. They sustain enormous abrasive velocities and pressures throughout their service application in wear industries, automotive manufacturing, and construction. These sectors use a variety of abrasive methodologies, from wet abrasive blasting to hydro-blasting. Sandblasting is the most common method, which involves projecting a continuous, pressurized stream of abrasive grit upon a surface to alter its composition.

Why Choose Ceramic Shot Blast Nozzles?

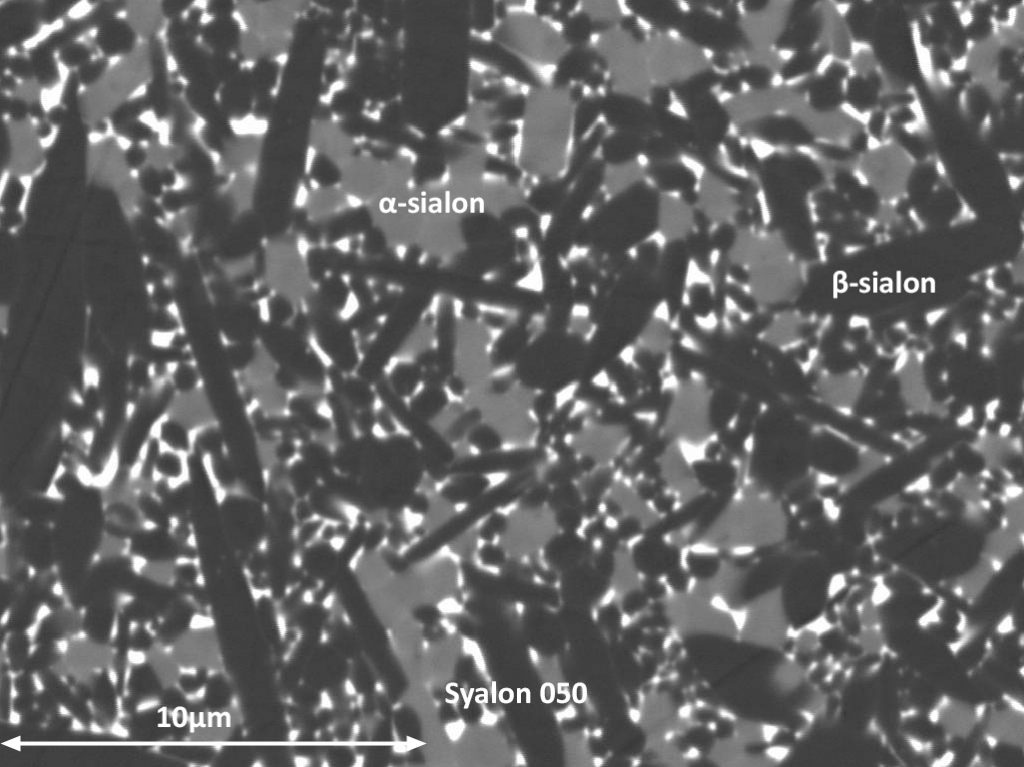

Silicon nitride ceramic-based shot blast nozzles are typically manufactured using Syalon 050. This speciality material features exceptional mechanical properties including high strength, hardness, and corrosion resistance. It is comprised of both alpha and beta phase silicon nitride grains that interlock in a completely impermeable structure, with 0% porosity ensuring that even minute abrasive particles cannot degrade the material’s robust mechanical bonds.

Syalon 050 was tailor-made for wear applications, where components must regularly resist numerous corrosive and abrasive elements. Shot blast nozzles are subject to regular abrasion from high-temperature and heavily pressurized media. Silicon nitride shot blast nozzles were designed to outperform conventional industry materials such as alumina (Al2O3) and tungsten carbide (WC), by providing advanced temperature resistances of up to 1450°C (2642°F) at pressures of up to 100 psi for demanding continuous operating hours.

Read more: Why Use Silicon Nitride Nozzles for Blasting, Extrusion & Flow Applications

The fracture toughness and elastic modulus of shot blast nozzle materials are integral for determining and optimizing its service life capacities. Corrosion-resistant alumina products typically exhibit a fracture toughness of up to 4.5 MPa, for example, providing good resistance to mechanical wear to reduce the risk of component failure. Syalon 050 exceeds those capabilities. It features a fracture toughness of 6.5 MPa, with a Young’s modulus of just 290 GPa. This enables Syalon 050 shot blast nozzles to withstand continuous, demanding operation for up to 1000 hours.

Shot Blast Nozzles from International Syalons

International Syalons is an industry-leading supplier of advanced ceramic materials for industrial applications. We have championed the potential of silicon nitride-based ceramics as an alternative to established industry materials and prepared a substantial range of products that prove the unparalleled quality of the material.

Our silicon nitride shot blast nozzles can be formulated from Syalon 050 in their entirety, or augmented with customized ceramic liners for application-specific requirements.

If you would like any more information about our shot blast nozzles, please do not hesitate to contact us.