Sialons are advanced technical ceramics based on silicon nitride (Si3N4). They retain the thermodynamic stability and exceptional toughness properties of silicon nitride due to their isostructural composition, but feature larger cell dimensions for the formation of high-density refractory components. This excellent molecular density enables outstanding resistance from severe corrosion and mechanical degradation, which are commonplace in industrial manufacturing environments. Sialons are therefore routinely used for the fabrication of wear components and thermally stable barriers for heat sensitive elements. Cutting tools, grinding media, and thermocouple protection sheaths are all commonly produced using materials from the sialon group.

Syalon 050 is distinct from other sialons for its improved corrosion resistant properties. All sialons exhibit good mechanical stability in the presence of common industrial corrosive elements such as acids and alkalis, but Syalon 050 was specifically designed to withstand the most demanding wear conditions. It is completely non-reactive to most industrial acids and alkalis at boiling temperatures, and is stable in the presence of molten aluminum for extended periods of exposure.

This article will explore the capacities and applications of Syalon 050 in more detail:

Specialized Corrosion Resistant Sialons

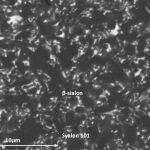

Syalon 050 is an α/β-sialon composite that is sintered to produce dense, interlocking needle-like grains and a fine equiaxed granular structure. This structural matrix is responsible for the material’s hardness rating of 94 HRA, creating a 0% porosity surface that is inherently resistant to an array of industrial corrosives and refractory temperatures. It can maintain this mechanical stability at continuous operating temperatures of up to 1400°C (2552°F), exhibiting total non-reactivity with molten aluminum, brass, and tin for metallurgical applications.

Sialons for Chemical Processing

Sialons are routinely used to improve chemical handling and transport processes in industrial chemical manufacturing and synthesis facilities. Tubes formulated from Syalon 050 have exhibited no reaction with common acids and alkalis such as acetic acid, hydrofluoric acid, and potassium chloride. These have been tested at 100% concentration and boiling temperatures for up to 100 hours of continuous exposure.

Sialons for Metal Handling

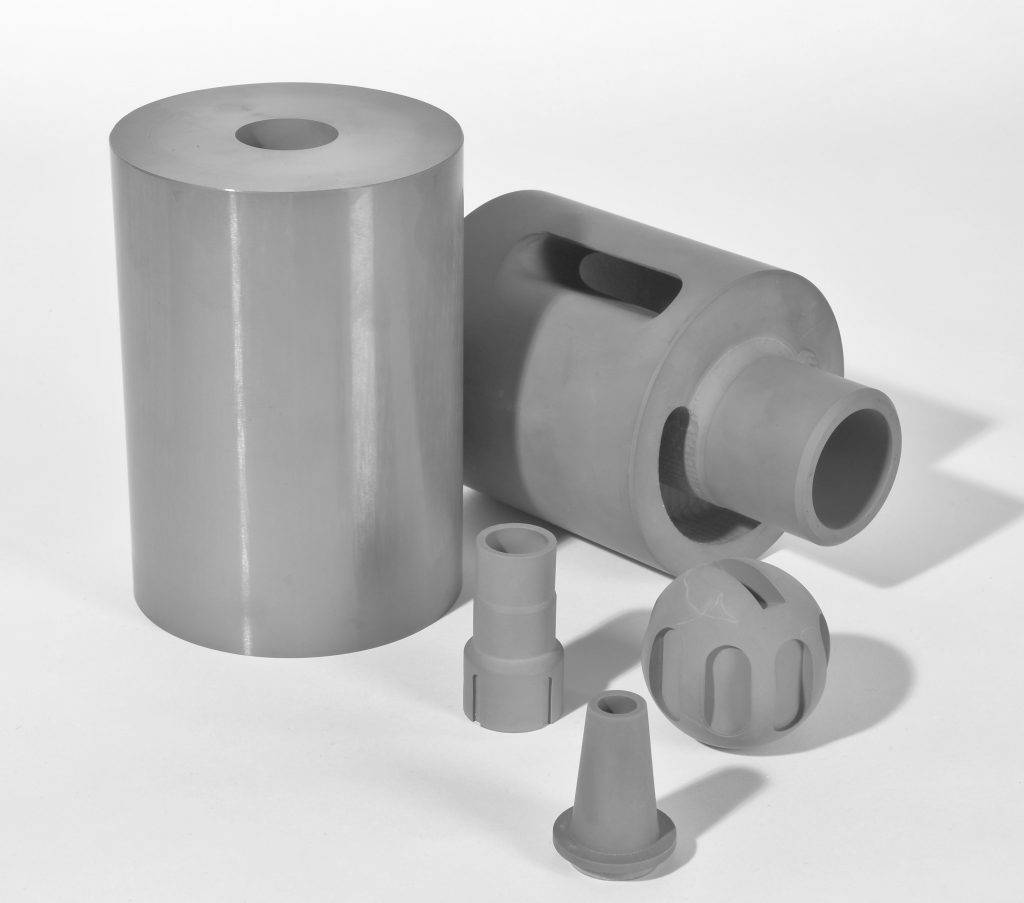

The improved hardness values of Syalon 050 and its high thermal shock resistance make it ideal for use in non-ferrous metal handling industries where temperatures exceed 1200°C (2192°F). Sialons are non-wetting to most metals in this sector, negating the risk of thermal spalling and molten-metal corrosion during processes such as hot dip aluminizing. Syalon 050 ceramic hooks are regularly used for these applications, with good degrees of machinability allowing facilities to form sialon hooks in a range of bespoke profiles.

Sialons for Metering Valves

A metering valve is a critical component in the oil and gas sector, and is used to control flow rates of corrosive materials through transport components. Syalon 050 is the sialon ceramic of choice for fabricating extremely tough metering valves for chemical and marine applications, providing security and reliability, and outperforming conventional metering valve materials by factors of up to 14 to 1.

Sialons from International Syalons

International Syalons is committed to innovation in the field of advanced ceramic materials. We have developed a range of distinct sialon materials with industry-specific properties, providing solutions to unique challenges and improving processes by offering alternatives to conventional materials.

If you would like any more information about Syalon 050, or any of our other sialon materials, please do not hesitate to contact us.