Ceramics have been utilised by mankind for millennia, mainly due to the abundance of raw materials and the relative ease with which basic pottery can be manufactured. Industrial production is of course more complicated than simple green kiln firing, but even advanced ceramics like aluminium oxide (Al2O3), boron nitride (BN), and zirconia (ZrO2) are derived from source materials that are relatively plentiful on earth. This is often used as an argument in favour of the eco-friendly credentials of technical ceramic materials.

So, does the primarily natural composition of ceramics mean they are an eco-friendly engineering solution? In this article, we will explore the role of ceramic materials in pollution with a few insights into the life cycles of advanced ceramic components.

Image Credit: Shutterstock

What Makes a Sustainable Material?

Global mass consumption has had a significant impact on the earth’s ecology, depleting non-renewable resources while simultaneously polluting the environment. Overwhelming evidence of manmade climate change has led to a gradual paradigm shift in favour of sustainable materials, which are defined as products that protect our environment throughout their entire life cycle. This means that raw materials must be ethically-sourced in order for finished ceramic materials to be truly sustainable.

Sustainable or not, ceramic materials are truly commendable when considering their negligible pollutive behaviour through their entire length of service and beyond.

Ceramic Materials: Non-Polluting Engineering Solutions

Most technical ceramics are principally non-polluting which means they are exclusively inert and non-toxic. Aluminium oxide (alumina) powder—for instance—is certified as safe for use in cosmetic products such as anti-perspirant deodorant, exhibiting little-to-no risk of cytotoxicity, immunotoxicity, reproductive toxicity, or bioaccumulation. Zirconia—meanwhile—is one of the most commonly used dental biomaterials worldwide. This excellent biocompatibility is a symptom of their inherent inertness, which also explains their lack of decomposition over time.

Another key indicator of sustainability is how well materials can be recycled and reused. As ceramic materials do not naturally degrade, they cannot be easily decomposed into raw materials for reformation. However, there are unique applications available for so-called ceramic waste once aggregated.

However, some engineers have turned this pitfall into a potential sustainable solution, using recycled crushed ceramic rubble (RCCR) to stabilise expansive soil and promote new breakthroughs in geotechnical engineering. Studies have shown that RCCR is technically practicable for stabilising expansive highly expansive soils (HES), meaning aggregated ceramic waste can continue to contribute to a healthy environment beyond its component life cycle.

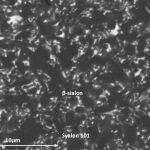

Image Credit: International Syalons (Newcastle) Ltd.

Advanced Ceramic Materials from International Syalons

At International Syalons, we supply a wide range of technical ceramic materials designed for enhanced performance capabilities. These enable engineers to deploy long-lasting solutions with tangible cost-savings and ecological benefits. Would you like to learn more? Contact a member of the International Syalons team today.

Source:

https://link.springer.com/article/10.1007/s40515-020-00120-z