Advanced ceramic materials continue to push engineering frontiers, and while there may be an open question about the true sustainability of technical materials from alumina (Al2O3) to zirconia (ZrO), there is no doubt about their impact on clean technology. We have spent the last few articles discussing the impact of advanced ceramic manufacturing on our environment, and their long-term viability in terms of pollution. In this article, we will explore the many exciting successes of sustainable advanced ceramic innovations and applications.

Appropriating Ceramic Waste

Although advanced ceramics are valued for their extreme robustness, the fact that they resist environmental degradation so well means that ceramic waste could languish in landfills for thousands of years. Sustainable engineers have tried to tackle this problem by appropriating ceramic waste and crushing it to use as an aggregate in structural concrete, or as a soil stabiliser. These successes may not only provide novel solutions to advanced ceramic waste but also facilitate a new era of more economical manufacturing and geotechnical engineering.

Read More: Are Ceramic Manufacturing Processes Environmentally Friendly? An Insight into Production

Environmental Engineering

This is a relatively new term that is separate from the likes of clean energy and sustainable innovations, as it refers to systems that actively protect our environment. One of the greatest successes in environmental engineering is the lambda sensor; an exhaust gas oxygen (O2) sensor that is used to monitor air/fuel ratios in vehicles and to provide feedback to catalytic converters for greater reductions in engine emissions. Advanced ceramics like alumina and zirconia are routinely used to generate lambda sensor components owing to their exceptional thermomechanical properties which allow them to withstand the harsh conditions of combustion engines for long periods of service.

Read More Technical Ceramic Sensors: Properties & Applications

Clean Energy

Adjacent to the growing environmental engineering sector is the more familiar market of clean energy. There is a wider consensus now that a global push towards clean energy is central to how we can preserve the natural systemic balance of our world’s ecosystems. This means dramatically cutting greenhouse gas emissions by moving towards hybrid and electric vehicles, while drawing our energy from renewable sources like solar and wind.

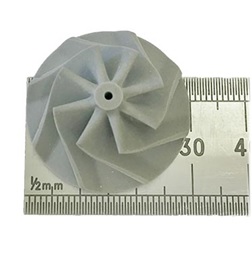

Read More 3D Printed Syalon Impellers for High Temperature Microturbines

Advanced ceramics continue to play a major role in clean energy generation, from solid oxide fuel cells (SOFCs) and high-temperature roller bearings in high-efficiency wind turbines to novel piezoelectric systems for solar exchangers. Innovations in additive manufacturing of technical materials is also allowing more intricate, long-lasting systems to be manufactured for hyper-efficiency energy conversion systems. 3D printed microturbines and impellers comprised of silicon nitride (Si3N4) for instance may provide a unique solution for hybrid vehicle motor recuperation.

Interested in learning how advanced ceramics could benefit your sustainability initiatives? Simply contact a member of the International Syalons team today to learn more.