Cleanliness, consistency, and regulatory compliance are key standards in the food industry, serving as non-negotiable requirements that must be met to minimise contamination risks, ensure efficient operations, and protect product integrity. From the machinery that processes food to the packaging that preserves it, food and beverage manufacturers require materials that are hygienic, durable, and thermally stable. One of these materials is aluminium, a metal valued for its versatility, corrosion resistance, and thermal performance, qualities that are harnessed through casting to produce food-grade components with precision and reliability.

Why the Food Industry Relies on Aluminium Casting

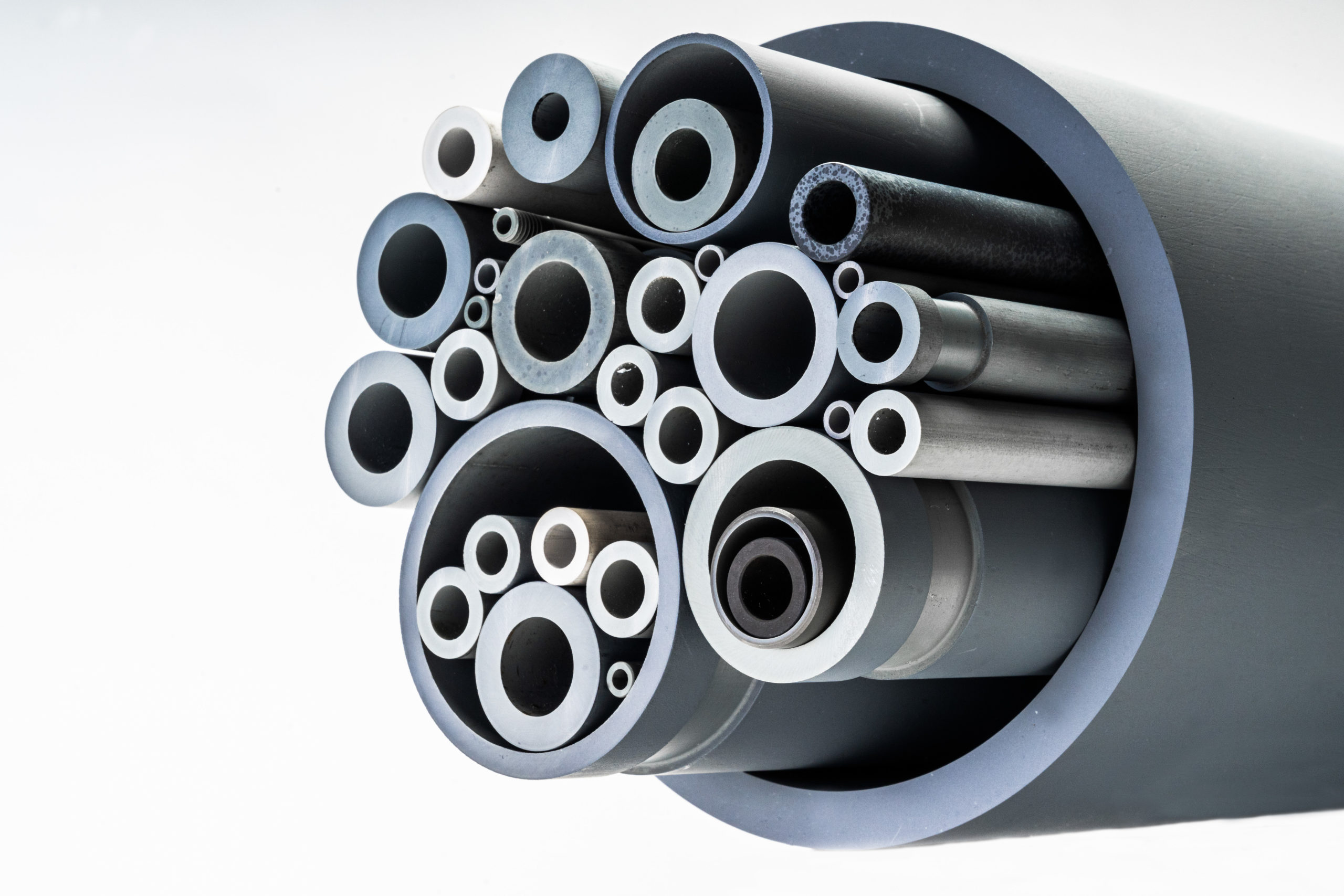

The food sector requires manufacturing solutions that can endure caustic cleaning agents, deliver stable thermal performance, and adhere to strict hygiene protocols. Aluminium is able to meet such criteria, and when used in casting, it offers unparalleled design flexibility, excellent heat conductivity, and inherent corrosion resistance. Its attributes make aluminium casting products ideally suited to a range of food-related applications, including commercial kitchenware, beverage production equipment, and sealed packaging systems. Furthermore, aluminium casting enables consistent, high-volume production with tight dimensional tolerances, which helps streamline operations and ensure compliance with food safety regulations. Taken together, these attributes position aluminium casting as an adaptable production method for delivering reliable food-grade components across the food and beverage industry.

Aluminium Casting Products for the Food Industry

Cast Cooking Surfaces

Cast cooking surfaces are aluminium castings engineered for direct food-contact heating in commercial and industrial settings. They include components such as griddles, waffle plates, and heating platens, all of which must meet demanding performance and hygiene standards.

- Design and production: Aluminium is cast into precise forms, often incorporating internal channels for heating elements or temperature regulation. Surfaces are then finished with food-grade coatings to prevent sticking and allow for easy cleaning.

- In the food industry: Applied to commercial grills, sandwich presses, conveyor toasters, and other high-volume cooking appliances.

- Advantages: Deliver rapid and even heat distribution, withstand repeated thermal cycling, comply with food contact regulations, and are easy to sanitise.

Die-Cast Equipment Components

Die-cast aluminium components provide the mechanical strength and durability needed in food processing systems to ensure reliable, hygienic, and long-lasting operation. These qualities are achieved through high-pressure casting, a process that produces accurate parts such as mixer housings, pump bodies, gear casings, and conveyor elements, all designed to resist mechanical stress, frequent cleaning, and exposure to food-safe chemicals.

- Design and production: Molten aluminium is injected into precision-engineered steel dies under pressure, rapidly forming detailed, complex shapes used in machinery across the food industry.

- In the food industry: Commonly used in enclosures, pump brackets, conveyor housings, and structural frames across processing and packaging lines.

- Advantages: Offer corrosion resistance, dimensional accuracy, high repeatability, and suitability for sanitary environments.

Aluminium Packing Moulds

Moulds and tooling utilised for food and beverage packaging can be formed through aluminium casting. These include moulds for aluminium cans, trays, and containers that must deliver precision and durability under continuous, high-volume production.

- Design and production: A mould block with complex cavities has aluminium cast into it, enabling the mass production of thin-walled food and drink packaging.

- In the food industry: Found in can-forming operations, foil tray manufacturing, and beverage packaging lines.

- Advantages: Provide dimensional stability, resistance to wear, long service life, and the ability to sustain high-throughput production with consistent results.

Ceramic Support Components for Aluminium Casting

Riser Tubes for Die Casting

Riser tubes, also called stalks, are specialised components in aluminium casting that facilitate the clean and controlled delivery of molten aluminium into mould cavities.

- How they work: Positioned vertically between the furnace and mould, riser tubes provide a sealed path for molten aluminium, reducing turbulence during injection.

- In the food industry: Employed in casting parts like pump housings, mixer frames, and enclosures used in food-grade processing equipment.

- Advantages: Prevent oxidation and porosity, promote even filling, and enhance the structural integrity of the final casting.

Silicon nitride heater and thermocouple protection tubes. Image Credit: International Syalons (Newcastle) Ltd.

Thermocouple Protection Sheaths

Thermocouple protection sheaths are essential support components in molten metal operations. Encased in ceramic, they safeguard sensitive thermocouples from chemically aggressive and high-temperature environments, preserving the accuracy of thermal readings.

- How they work: A ceramic sheath encases the thermocouple and is inserted into molten aluminium, producing a barrier that deflects chemical reactions and physical damage while allowing for precise temperature measurement.

- In the food industry: Used for monitoring furnace conditions during the casting of food-safe aluminium components.

- Advantages: Enhance temperature accuracy, extend sensor lifespan, reduce maintenance requirements, and improve overall casting consistency.

Silicon nitride thermocouple protection tubes. Image Credit: International Syalons (Newcastle) Ltd.

Immersion and Radiant Heater Tubes

Immersion and radiant heater tubes are support components that protect internal heating elements from corrosive exposure. These tubes ensure efficient heat transfer and stable furnace operation.

- How they work: Immersion heaters operate submerged in molten aluminium, whereas radiant heaters are positioned above. Both types transfer heat indirectly, protecting sensitive elements from damage.

- In the food industry: Help maintain consistent melting conditions in the furnaces used to produce cookware, trays, and packaging components.

- Advantages: Increase heater longevity, ensure thermal uniformity, minimise contamination, and promote energy-efficient operation.

Achieving Clean and Efficient Food and Beverage Production with Aluminium Casting Products

Aluminium casting products are integral to performance, safety, and adherence to industry regulations in food and beverage manufacturing. Their reliability and adaptability enable streamlined production processes and support the hygiene requirements of modern food facilities. International Syalons supports aluminium casting processes by providing advanced ceramic components for molten aluminium handling. Our thermocouple protection sheaths, heater tubes, and riser stalks are engineered to facilitate the efficient and safe manufacture of aluminium parts for food industry applications. To learn more about our aluminium casting solutions, speak to our experts today.