The depletion of existing hydrocarbon supplies and reserves is well-documented, with the oil and gas industry becoming increasingly circumspect in its attempts to meet a growing demand with a dwindling supply. Petroleum geology and natural gas exploration has transformed in recent years, augmenting traditional prospecting methodologies with new and emerging technologies. Fracking enables oil and gas suppliers to withdraw hydrocarbons dispersed in the strata of the earth’s crust, but this methodology is divisive from an ethical and environmental perspective.

Improving the efficacy of offshore facilities by increasing their exploratory range and extraction capabilities is considered a priority by many in oil and gas applications. This requires unique materials capable of withstanding the significant erosive and corrosive forces of sub-sea applications. These severe, high-pressure environments pose significant risks for conventional materials that can become damaged through oxidation, salt-water erosion, and tidal abrasion. Even hard-wearing metals such as alumina will gradually degrade under these demanding conditions.

Sialon ceramics represent an ideal solution for these environments, offering a high-performance replacement for even hard-wearing metals such as alumina. This article will explore the benefits of using syalon materials in the oil and gas sector in more detail:

Corrosion Resistant Ceramics for Oil & Gas Applications

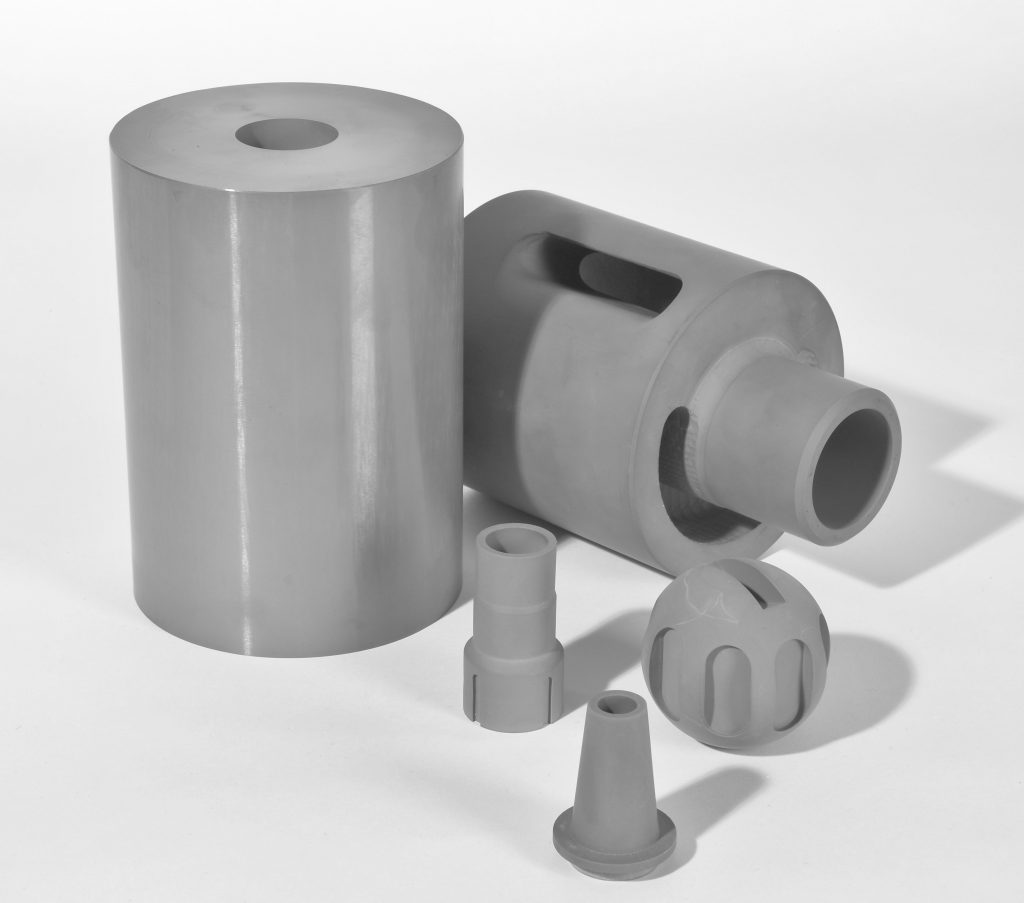

Sialon Hydrocyclones

Hydrocyclones are critical components for sub-sea hydrocarbon extraction processes. They are used to separate sand and solid particulates from oil through centrifugal force. The extracted slurry exhibits significant differences in pressure, which generates a rotational force within the component. This force gradually turns the solution, causing a flow that separates larger, solid particles from the oil.

This process is critical for providing high-purity petroleum for commercial use, but it is associated with significant abrasive forces that can cause conventional components to prematurely fail. The oil and gas sector has resolved this longevity and stability issue by applying sialon liners to hydrocyclone components.

These high-toughness sialon ceramics feature a 0% porosity for exceptional resistance to fine particle abrasion under the most demanding applications. They can comprehensively resist the corrosive and abrasive forces of oil and gas slurry filtration.

Sialon Metering Valves

Metering valves are responsible for monitoring the abrasive, high-temperature flow of oil and gas slurries. These components are subject to numerous corrosive elements, from chemical abrasion to thermal deformation. Yet their mechanical stability throughout service is paramount to the efficacy of integral oil and gas processes.

Syalon 050 is the ideal material for providing extending the service lives of metering valves in hydrocarbon slurries. It is the hardest of our sialon grades, and has been optimized for comprehensive chemical resistance at high temperatures. This robust chemical stability has been tested in heated and abrasive slurry oil and gas slurry applications, and has been proven to out-perform conventional materials by factors of up to 14:1.

Looking for High-Performance Ceramic Solutions for Oil & Gas Applications?

International Syalons is a leading supplier of unique material solutions for some of the most demanding applications on earth. Our technical ceramics are suitable for severe sub-sea applications and are proven to outperform conventional materials and other technical ceramics such as silicon carbide in harsh oil and gas applications.