Understanding the relationship between microstructure and ceramic properties is essential for the development of high-performance, advanced ceramic materials. Ceramic materials, particularly silicon nitride ceramics, exhibit a variety of unique properties, such as high strength, thermal shock resistance, and oxidation resistance, making them ideal for demanding applications. However, these properties are highly dependent on the material’s microstructure, which is governed by parameters such as grain size, shape, and distribution.

The Integral Role of Grain Size in Determining Properties of Silicon Nitride

At the heart of ceramic microstructure are small crystals known as grains. The grain size significantly influences the mechanical and thermal properties of silicon nitride. Studies have shown that smaller grains lead to denser and stronger ceramic materials. This relationship between grain size and strength is especially pronounced in hot-pressed silicon nitride, with high-temperature sintering resulting in fully dense silicon nitride with a typical α-Si3N4 equiaxed structure.

Enhanced fracture toughness, microhardness, bending strength, and even Vickers hardness are attributable to a uniform microstructure devoid of abnormal grain growth. Moreover, silicon nitride ceramic balls exhibit increased relative density, hardness, and crushing load with a decrease in the particle size of silicon nitride. Therefore, a controlled grain size is crucial for achieving high strength and advanced mechanical properties in silicon nitride ceramics.

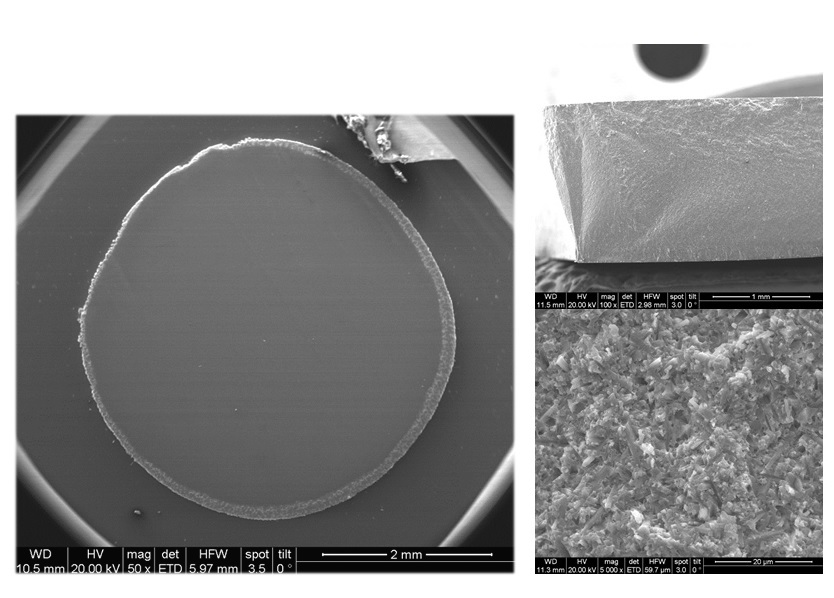

SEM and optical microscopy images showing the microstructure of a Syalon 101 (beta-sialon) fracture surface. Image Credit: International Syalons (Newcastle) Ltd.

The Influence of Microstructural Parameters on Thermal Properties

Aside from mechanical characteristics, the thermal properties of silicon nitride also correlate with its microstructure. Silicon nitride’s thermal conductivity and thermal shock resistance are impacted by its grain size, the presence of secondary phases, and texture. Si3N4 materials with differing microstructures, prepared via hot isostatic pressing, revealed distinct thermal properties based on holding time at maximum temperature.

The thermal diffusivity of hot-pressed silicon nitride, for instance, increases with β-content, attaining maximum thermal diffusivity at approximately 3 wt% MgO. Intergranular glassy phases and their distribution also affect the thermal conductivity of silicon nitride. Variations in the composition of these glassy phases influence the degree of stress accumulation and the occurrence of devitrification. Thus, careful engineering of the microstructure can optimize the thermal properties of silicon nitride ceramics.

The Relevance of α-β Sialon in Microstructure and Ceramic Properties

A discussion on the microstructure of silicon nitride ceramics would be incomplete without mentioning α/β-sialon composites. Sialons are solid solutions of silicon nitride and represent a family of advanced ceramics with superior wear resistance, thermal shock resistance, and high strength. The presence of α- and β-sialon phases in the microstructure of silicon nitride ceramics significantly influences their material properties.

A distinct attribute of silicon nitride ceramics is the hexagonal crystal structure of the β-Si3N4 phase, which produces a strong and tough ceramic due to its interlocking needle-like microstructure. While the fine equiaxed crystalline grain structure of α-sialon results in very high hardness. Consequently, the microstructure of silicon nitride ceramics, including the presence of sintering additives to create a α/β-sialon composite ceramic, substantially affects its thermomechanical properties.

Syalon 101 (beta-sialon) weld location pins. Image Credit: International Syalons (Newcastle) Ltd.

The Microstructural Blueprint for High-Performance Ceramics

It is clear that the microstructure plays a pivotal role in determining ceramic properties, notably in silicon nitride ceramics. By manipulating the microstructural characteristics such as grain size, relative density, and careful control of α- and β-sialon, phase content it is possible to design ceramics with enhanced material properties and performance capabilities. Understanding this microstructural blueprint is vital for scientists and engineers seeking to create the next generation of advanced ceramic materials with superior strength, thermal conductivity, and wear resistance. These endeavours underlie research and development into cutting-edge applications where engineers push the frontiers of materials science.

If you have found this post interesting and want to learn more, read our deep dive into the atomic structure of silicon nitride. Otherwise, contact a member of the International Syalons team if you have any questions.