Technical ceramics represent the cutting-edge of industrial materials. Engineered to withstand some of the harshest operating conditions ever conceived, technical ceramics are increasingly pushing the frontiers of market segments around the world.

Also known as advanced or engineering ceramics, technical materials are designed to meet specific demands with regard to aggravating phenomena. These may include aggressive corrosive and erosive elements, extreme operating temperatures, high physical stresses, or any combination of the three. Due to their uniquely tailored material properties, technical ceramics can exceed in conditions where conventional materials would inevitably fail. This has unlocked new levels of performance in conventional markets while contributing towards the practical actualization of various blue-sky applications.

Technical Ceramic Material Groups

Numerous technical ceramic groups are available on the market today, but the underlying classification defines them as high-performance components comprised of strong inorganic compounds. At the chemical level, these are typically held together by high strength covalent bonds that form sturdy structural lattices. The outstanding thermomechanical and chemical properties of these perpetuate through to the semi-crystalline microstructure, ultimately translating into a robust bulk monolithic ceramic.

International Syalons supplies a selection of high performance technical ceramic materials, including:

- Silicon nitride (SiAlON): At International Syalons, we specialize in the silicon-nitride derivatives known as sialons, an exceptional all-round technical ceramic with finely tunable

- Zirconia (ZrO2): With unmatched toughness, technical ceramics based on zirconium oxide are ideal for hard-wearing applications, from dentistry to metal forming.

- Alumina (Al2O3): The eponymous technical ceramic, alumina belongs to the oxide ceramic group and is the most widely used engineering ceramic worldwide.

- Silicon carbide (SiC): With outstanding thermomechanical and non-corrosive properties, technical ceramics based on silicon carbide are ideal for use in the chemical industry.

Material Properties of Technical Ceramics

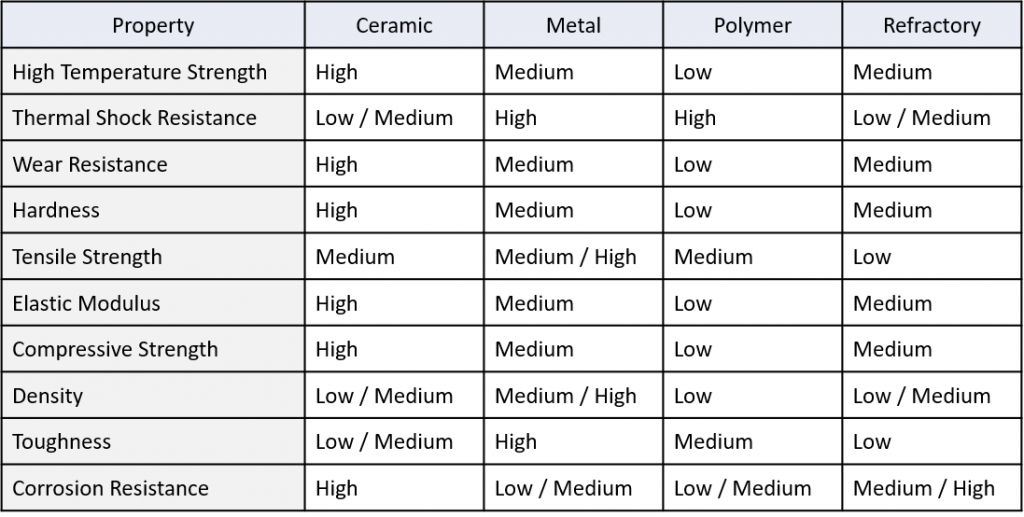

The desirable material properties of distinct technical ceramics vary from group-to-group, and even within certain families. Generally-speaking, engineers require a good spectrum of properties to guarantee success in demanding application areas. Key ceramic properties for industrial areas of application include:

- Modulus of rupture (MoR); expressed in megapascals (MPa) at both room temperature and refractory temperatures (>1000°C).

- Hardness; typically measured via indentation according to the Vickers test and expressed as a function of load over the indentation surface area (Kg/mm2).

- Fracture toughness; measured by first acquiring the technical ceramic’s Young’s modulus and measuring the force required to cause a known defect to propagate (MPa m1/2).

- Thermal shock resistance; expressed as a change in temperature (ΔT °C).

- Thermal conductivity; measured by characterizing the mineralogical composition and density of the technical ceramic according to Fourier’s law, and expressed in Watts per meter-Kelvin (W/(mK)).

A Brief History of Technical Ceramics

The term linear pottery culture refers to what is known as an archaeological horizon, which is a consistent trait found across a wide geographical area for a limited time. It covers the period when numerous communities worldwide simultaneously discovered different processes for fabricating ceramic materials. These rudimentary artifacts are some of the world’s oldest examples of early industry.

Technical ceramics originated thousands of years later when coke was introduced to the smelting process to increase material yields. This innovation directly led to the formation of silicon carbide ceramics almost two centuries later. The use of coke in smelting also preceded the invention of the Bayer process, which presented a method for refining bauxite ore into alumina.

- For more information, read The History of Sialon Ceramics

While these technical ceramic innovations arose during the early industrial eras, equivalent breakthroughs in ceramic engineering for silicon nitride were not seen until comparatively recently. The discovery of sialons in the 1970s was a ground-breaking technical achievement that made high-strength silicon nitride a truly competitive material in the technical ceramics space. New, previously inconceivable developments have shown the compatibility between advanced sialons and proprietary additive manufacturing techniques.

International Syalons: Technical Ceramics Suppliers

International Syalons is an industry leader in the development and supply of high-performance technical ceramics for industrial applications. We provide unmatched material solutions for demanding areas of application, servicing industries as varied as:

- Chemical and process.

- Industrial wear.

- Metal forming.

- Molten metal handling.

- Oil and gas.

If you would like to learn more about any of the topics discussed in this article, we have written extensively on each of the overview topics. If you would like to learn more about the unique properties of sialons, read our introduction to the material: What are Sialon Ceramics? Or, if you are more interested in the future of the material, you might like our post Introducing Additive Manufacturing for Silicon Nitride Ceramics.

Otherwise, contact a member of the International Syalons team today if you have any questions about our technical ceramics capabilities.