International Syalons are now halfway through the 3 year ToMax project and are working closely alongside consortium partners Lithoz to develop lithographic additive manufacturing technology (L-AMT) for silicon nitride materials.

The EU funded Horizon 2020 project has united industrial know-how from across Europe in the fields of software development, photopolymers and ceramics, high performance light-sources, system integration, life cycle analysis, industrial exploitation and rewarding end-user applications, with the end goal of producing 3D-printers with high throughput and outstanding materials and energy efficiency.

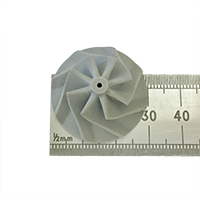

The ToMax consortium is taking innovative, resource-efficient manufacturing processes to develop energy-efficient L-AMT machinery, with a focus on manufacturing of alumina, silicon nitride and cermet parts with high shape complexity for aerospace and automotive engineering, medical devices, and energy efficient lighting applications.

Results so far have been ground-breaking as the project has already produced fully dense, extremely complex Syalon 101 and 050 grade parts with excellent surface quality, and initial testing indicates the same mechanical properties as conventionally fabricated Syalon 101, as shown in the table below.

The Board are proud to announce that ISN have recently recruited two apprentices to work in our ‘green’ machine department. Luke Walker and Sean Dalziel have been with us for several months and are making excellent progress in a highly skilled and critical process area. With the success of this trial the Board are keen to recruit further apprentices next year.

The Board are proud to announce that ISN have recently recruited two apprentices to work in our ‘green’ machine department. Luke Walker and Sean Dalziel have been with us for several months and are making excellent progress in a highly skilled and critical process area. With the success of this trial the Board are keen to recruit further apprentices next year. The Board are proud to announce that ISN are sponsors of Backworth Cricket Club (BCC) in the North East of England. ISN has a long association with cricket as our Operations Director, Ian Denton and Sales Engineer, Aidan Love are former players.

The Board are proud to announce that ISN are sponsors of Backworth Cricket Club (BCC) in the North East of England. ISN has a long association with cricket as our Operations Director, Ian Denton and Sales Engineer, Aidan Love are former players. The Board are pleased to announce the appointment of Simon Dodd as Sales Manager with immediate effect. Simon, who has more than 10 years of advanced materials sales experience, will be responsible for generating new business to help continue the excellent sales growth we have achieved in the last few years.

The Board are pleased to announce the appointment of Simon Dodd as Sales Manager with immediate effect. Simon, who has more than 10 years of advanced materials sales experience, will be responsible for generating new business to help continue the excellent sales growth we have achieved in the last few years. To coincide with the launch of our redesigned website ISN has recently increased our portfolio of advanced engineering ceramics. In addition to the various grades of

To coincide with the launch of our redesigned website ISN has recently increased our portfolio of advanced engineering ceramics. In addition to the various grades of  o Spray Drier to allow us to work on developing new materials and composites. In green machining we have installed another new XYZ 4-axis CNC turning centre while in grinding we have installed a new Andmar Surface Grinder. To cope with the increased demand and complexity of parts we invested in a new Mitutoyo CNC Co-ordinate Measuring Machine at the end of last year which is now fully commissioned. We are continually making significant investments in new equipment to ensure the company can meet the increased demand while maintaining acceptable delivery times.

o Spray Drier to allow us to work on developing new materials and composites. In green machining we have installed another new XYZ 4-axis CNC turning centre while in grinding we have installed a new Andmar Surface Grinder. To cope with the increased demand and complexity of parts we invested in a new Mitutoyo CNC Co-ordinate Measuring Machine at the end of last year which is now fully commissioned. We are continually making significant investments in new equipment to ensure the company can meet the increased demand while maintaining acceptable delivery times.