Technical ceramics are among the most advantageous engineering materials ever developed, characterized by a diverse range of chemical, electrical, and thermomechanical properties. From hard-wearing silicon carbide (SiC) armour plates to piezoelectric zinc oxide (ZnO), components based on fine ceramic materials have permeated a broad range of market sectors. This far-reaching applicability stems from the compositional variety of ceramic compositions.

Continue readingCategory Archives: Uncategorized

What is Alumina?

Alumina (Al2O3), otherwise known as aluminum oxide, is an advanced refractory belonging to the oxide group of technical ceramics. It is an extremely versatile material that can be bonded and formed using a broad range of consolidation and sintering techniques, yielding precise near-net shapes in a range of purities.Continue reading

A Guide to Electro Discharge Machining (EDM) of Sialon Ceramics

Technical ceramics are unique among structural materials for their extraordinary performance in challenging conditions. While each specific beneficial thermal or mechanical property depends on both the underlying material and the application, technical ceramics are typically renowned for their:

Technical Ceramics for Welding Applications

There are a myriad of different welding methods available today, such as metal inert or metal active gas (MIG/MAG) welding, high-frequency electric resistance welding (HF-ERW), shielded metal arc welding (SMAW), and many more. Technical ceramics can be used in tandem with practically any welding type, but they are typically restricted to high-value industrial processes due to their relatively high costs.

Continue readingFestive Holidays Notice

International Syalons (Newcastle) Ltd. offices will be closed from Friday 20th December until Monday 6th January.

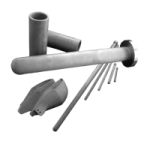

Why Use Silicon Nitride Nozzles for Blasting, Extrusion & Flow Applications

Silicon nitride (Si3N4) ceramics offer some of the best-in-class tribological properties, with outstanding nominal fracture toughness (Syalon 101 = 7.7 MPa m1/2) and exceptional strength characteristics (compressive, flexural, etc.). This combination gives silicon nitride outstanding wear resistance. The result is that a component fabricated from advanced ceramics like silicon nitride can withstand significant ongoing stress throughout its service life. This makes it the ideal ceramic material for dies, weld rolls, and cutting tools for example.

Continue readingHow Advances in Technical Ceramics Aid Industry 4.0

Updated 25/05/2022:

Digitalization and enhanced automation in industrial settings are now ushering in a fourth industrial revolution (Industry 4.0), which is fundamentally fuelled by advances in materials like technical ceramics.

Continue readingComparing Technical Ceramics: Sialon vs Zirconia

ww.syalons.com/materials/silicon-nitride-sialon/Technical ceramics like sialons and zirconia are among the most advanced materials ever engineered by mankind, enabling new application areas that were practically impossible before their commercial realisation. With many technical ceramics, there is a substantial overlap between their thermomechanical and chemical properties, which can complicate ideal material selection for distinct applications. In the case of sialons and zirconia however, the materials can be easily and respectively distinguished as a non-oxide and an oxide ceramic.

Continue reading25 Years of Service Anniversaries

Last week two long-serving employees of International Syalons (Newcastle) Ltd. celebrated their 25 Years of Service Anniversary.

A Guide to Technical Ceramics

Technical ceramics represent the cutting-edge of industrial materials. Engineered to withstand some of the harshest operating conditions ever conceived, technical ceramics are increasingly pushing the frontiers of market segments around the world.

Continue reading